The introduction of the standard ISO 21307 says:

With the increasing use of bimodal polyethylene (PE) materials such as PE 80 and PE 100, more and more PE compounds are appearing on the pipe market accompanied by proposals for butt fusion procedures that often differ for the same materials. The aim of standardization is to encourage the use of similar procedures for similar materials. There is a need to examine current practice on a global scale and establish the best procedure(s) for the highest-quality, most reliable and efficient construction of PE butt fusion systems for gas and water distribution.

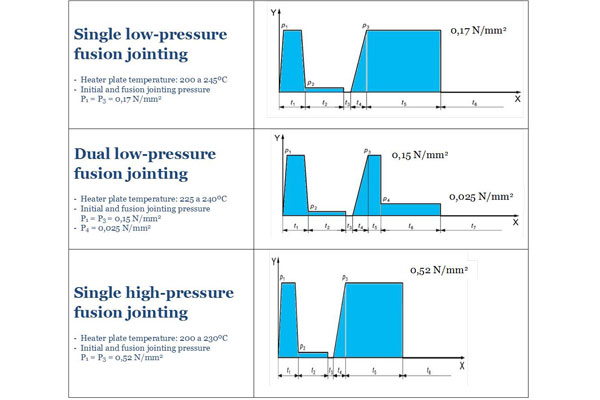

The standard ISO 21307 contemplates the 3 following procedures:

NOTES:

- It is important that pipe or fitting manufacturers and equipment manufacturers be consulted when undertaking butt fusion jointing of pipes with a wall thickness greater than 70 mm.

- The dual low-pressure fusion jointing procedure is only applicable for pipes with a wall thickness greater than 20 mm.

- The single high-pressure fusion jointing procedure is applicable for pipes or fittings with a wall thickness of minimum 5 mm up to and including 70 mm.

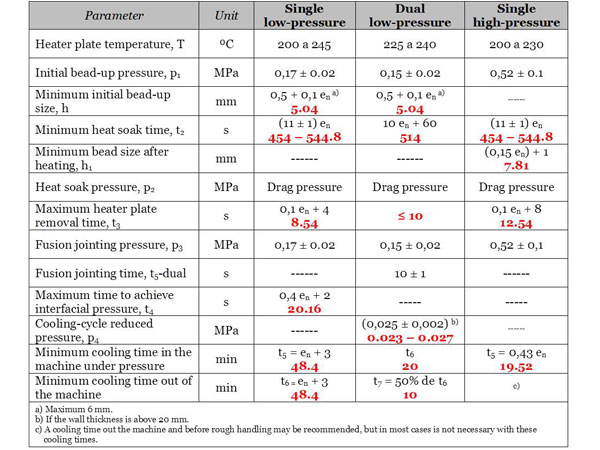

Calculation of the parameters of welding

Pipe or fitting: PE 100 DN 500, SDR 11, wall thickness (en) 45.4 mm, PN 10 bar.

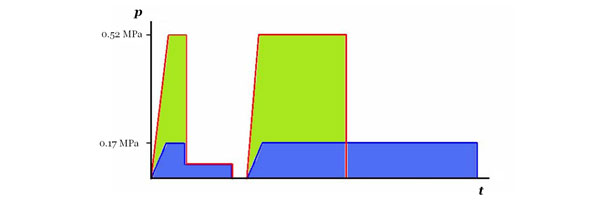

Systems compared low and high pressure single

As shown in the graphs of the various systems, the high pressure method of butt welding takes less time to make a weld than low pressure. This is a very important factor in lowering the cost of installation, since the cycle times necessary for butt welding large diameter pipes are long. Using the high pressure method means that daily productivity can be significantly increased.

Reference

ISO 21307-2011

Plastics pipes and fittings – Butt fusion jointing procedures for polyethylene (PE) pipes and fittings used in the construction of gas and water distribution systems,

>>> Do you agree with the calculation of butt welding parameters?

Deja tu comentario