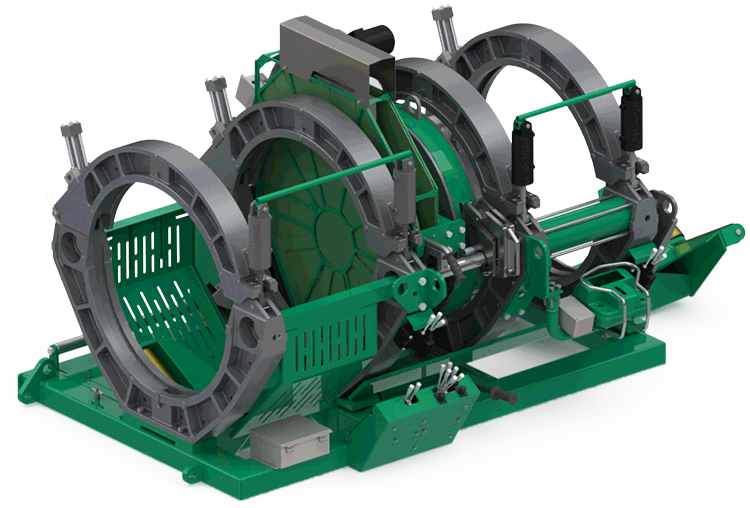

TRACSTAR 28 SERIES 2

2″ IPS – 8″ DIPS (63mm – 225mm)

Based on our clients’ own field experiences, we have designed and built the new Tracstar 28 Series 2. A new fairing system facilitates the dissipation of heat generated by the machine while providing easier access at the same time. perform the maintenance of the machine. It also has an updated electrical system with the latest technologies in the sector, providing greater safety of the electrical circuit and a standard battery disconnection for a simpler block.

This machine is also available as a combined unit, for its fusion of branch frames and an automated machine.

PARTS & ACCESSORIES FOR THE DYNAMC 28

Highlighted substitution parts and accessories

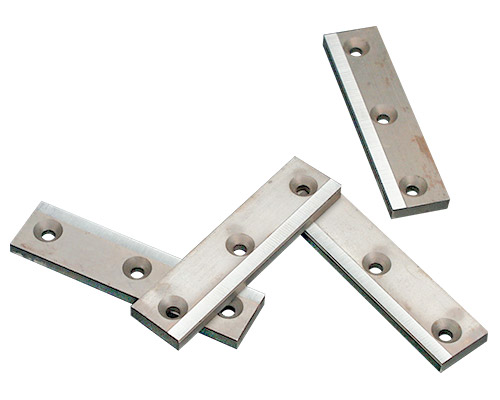

Butt Fusion & Mitered Insert Sets

Surface hardened for longer life and are serrated for maximum grip.

DataLogger® 6

Collect and analysis of data on all your fusions

Automated In-Ditch Extension Kit

Set of four 25′ hydraulic extension hoses and extension cables and pendant strap. This kit is required for automated in-ditch fusion. Set of four 25′ hydraulic extension hoses, extension cable, facer stand and pendant strap.

Blade set

Spare 4 set facer blades, extended life facer blade set and cardibe blades for abrasive materials.

Facer Stand

Facer stand provides a convenient place to protect and store your facer out of the dirt and mud.

Heat Shield

For fusing two materials with different melt rates. Shields the faster melt rate materials from over melting.

Heater Caddy

The Heater Caddy allows you to use the machine to easily carry the heater with the stand from joint to joint. Retrofit Kit for TracStar 28/250 machines built before 9/2010. Allows the heater and heater bag frame to attach to a TracStar.

Heater Stand

Holds heater for easier carrying and protection. Helps maintain constant temperature.

Heaters

Heaters have a microprocessor control and a dial thermometer to monitor temperature. 220-240V, 50/60Hz, 1Ph Heater. 100-120V, 50/60Hz, 1Ph Heater.

Hot Tap Tool

Branch saddle tapping tool for polyethylene pipe.

Hydraulic Extension Hoses

Required for in-ditch fusion. 25ft Extension Hose Set (4 hoses).

Pipe Support Stand

Height is adjustable to properly support, position and align pipe to be fused. 8″ Pipe Stand.

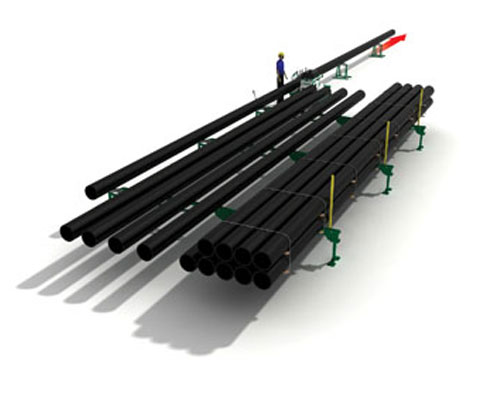

PolyHorse®

Pipe handling system that consists of a series of adjustable racks to store and help install pipe on the job site. Standard PolyHorse. PolyHorse with Power Assist.

PolyPorter®

Aids in lifting pipe into the fusion machine and also performs as a pipe stand.

Pyrometer Kit

Pryometer kit for accurately checking surface temperatures of heater. Measures surface temperature of heater.

Self-Centering Stub End Holder

Self-centering stub end holder to hold stub end for butt fusion.

Shipping Container

Self-centering stub end holder to hold stub end for butt fusion.

Spare Auto Pendant

Reusable shipping container.

Spare Auto USB Thumb Drive & Adapter

Used for downloading fusion records from the Auto Pendant to a USB thumb drive. For use with Pendant 1 models.

Spare Automated Control Box

Spare control box for quick replacement. For use with Automated TracStar Series 2 machines.

Spare Heater Plate Kit

Heater plates have an anti-stick coating and are required for butt fusion.

Test Caps

Quick and easy air pressure testing of polyethylene pipe.

Toolbox with Tray

For organizing your inserts and adapters for safe keeping. For organizing your inserts and adapters for safe keeping.

SPECIFICATIONS

| TracStar® 28 Series 2 | TracStar® 28 Series 2 Combination Unit | |

| Machine | 1,930 lbs (875.4 Kg) | 1,930 lbs (875.4 Kg) |

| 4-Jaw Carriage/strong> | 221 lbs (100.2 Kg) | 267 lbs (121.1 Kg) |

| 3-Jaw Carriage | 142 lbs (64.4 Kg) | 188 lbs (85.3 Kg) |

| Facer | 44 lbs (19.9 Kg) | 44 lbs (19.9 Kg) |

| Heater | 21 lbs (9.5 Kg) | 21 lbs (9.5 Kg) |

| Shipping Weight | 2,365 lbs (1,072.8 Kg) | 2,410 lbs (1,093 Kg) |

| TracStar® 28 Series 2 | TracStar® 28 Series 2 Combination Unit | |

| System Pressure | 2,000 PSI (137.90 BAR) Max. | 2,000 PSI (137.90 BAR) Max. |

| Hydraulic Reservoir Capacity | 8 Gallons (30.28 Liters) | 8 Gallons (30.28 Liters) |

| TracStar® 28 Series 2 | TracStar® 28 Series 2 Combination Unit | |

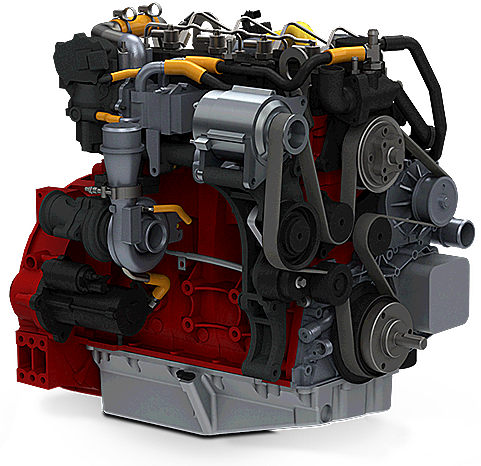

| Engine Type | 20 HP Liquid Cooled. | 20 HP Liquid Cooled. |

| Fuel Type | Diesel | Diesel |

| Fuel Tank Capacity | 5 Gallons (18.92 Liters) | 5 Gallons (18.92 Liters) |

| Operational Tank Capacity | 8 Hours | 8 Hours |

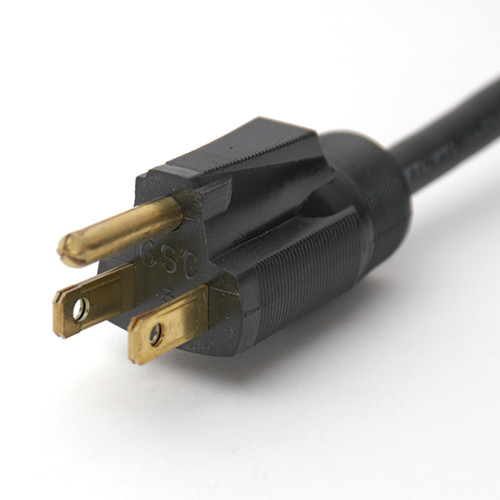

| Starting System | Electric | Electric |

| TracStar® 28 Series 2 | TracStar® 28 Series 2 Combination Unit | |

| Input | None, self-contained | None, self-contained |

| AC Output | 120V & 240V, 60Hz, 15 Amp | 120V & 240V, 60Hz, 15 Amp |

| TracStar® 28 Series 2 | TracStar® 28 Series 2 Combination Unit | |

| Heater Power | 3,000 Watt | 3,000 Watt |

| Facer Power | Hydraulic | Hydraulic |

| TracStar® 28 Series 2 | TracStar® 28 Series 2 Combination Unit | |

| Frame | Welded steel construction | Welded steel construction |

| Brake | Self-locking | Self-locking |

| TracStar® 28 Series 2 | TracStar® 28 Series 2 Combination Unit | |

| Tracked | Rubber crawler tracks | Rubber crawler tracks |

| Transportation | Self-propelled | Self-propelled |

| Vehicle Speed | 1.5 MPH max | 1.5 MPH max |

| Lifting | Lift points and lifting assembly | Lift points and lifting assembly |

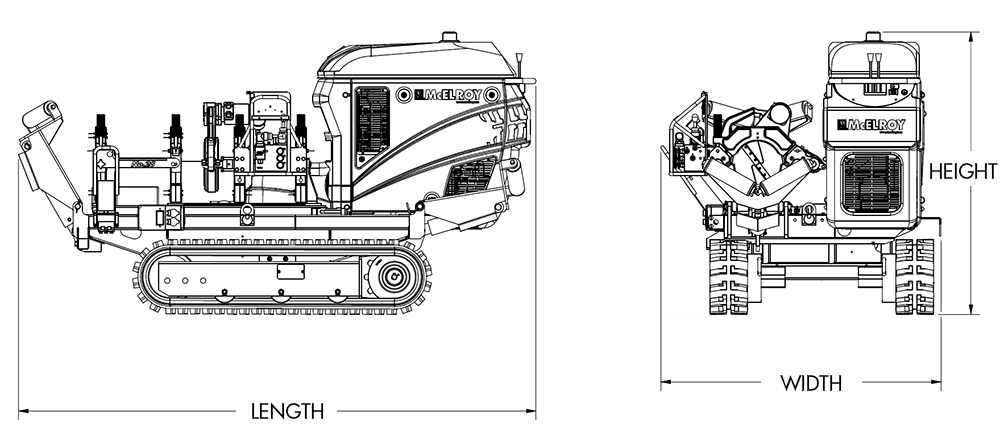

| TracStar® 28 Series 2 | TracStar® 28 Series 2 Combination Unit | |||

| Machine | Shipping Container | Machine | Shipping Container | |

| Length | 97.2″ (2,464 mm) | 90″ (2,286 mm) | 97.2″ (2,464 mm) | 90″ (2,286 mm) |

| Width | 52.6″ (1,336 mm) | 60″ (1,524 mm) | 52.6″ (1,336 mm) | 60″ (1,524 mm) |

| Height | 53.1″ (1,348.7 mm) | 63″ (1,600 mm) | 53.1″ (1,348.7 mm) | 63″ (1,600 mm) |

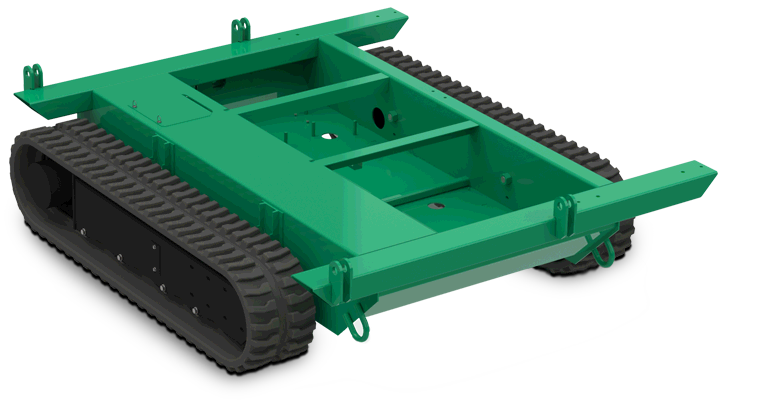

A NEW REVOLUTION FOR THE INDUSTRY

Ease of movement and maneuvering to make long pipe mergers is possible with the number one market option, the TracStar. Instead of wheels they have rubber tracks that are self-propelled and allow these machines to overcome irregular terrain and climb slopes of up to 30%. All Tracstar have independent electrical equipment. The trolley is mounted on the chassis itself and is driven by tracks to make the loading of the pipe and the movement along the pipe even easier. The car can also be disassembled to work in tight spaces like a trench. The Tracstar is available in all types of sizes for melting tubers from 2 «IPS to 48» OD.

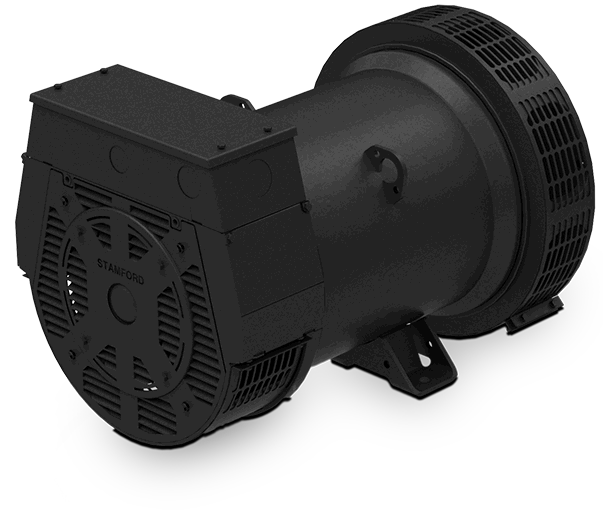

SELF-CONTAINED

DIESEL ENGINE

MORE PRODUCTIVITY AT WORK

All our Tracstar machines have a self-contained liquid-cooled or turbo-diesel engine. These engines have a fuel tank large enough to merge and be operating for a full day of work. Our newest and largest model, the Tracstar 1200, comes with an emission control engine with the latest advances that meets all industry standards. Tier 3 of the EPA, which eliminates the need for diesel exhaust fluid (DEF).

READY FOR

THE DITCH

REMOVABLE TRANSPORTATION FOR USE IN REDUCED SPACES

All our machines in the Tracstar range come with an interchangeable 4-jaw carriage. This can be removed very easily to perform mergers in smaller spaces and ditches. The outer clamp and skid can also be removed from the cart. So we turn it into a 3-jaw car and we have a smaller fusion machine.

VEHICLE MOUNTED

ON THE TRACK

WORK UP TO THE HEAVIEST TERRAINS

The Tracstar has double rubber tracks to move with ease on any terrain, whether mud, snow or desert sand, the Tracstar are able to overcome up to 30% slopes. Its track wheel system has a zero-degree turning radius that shoots the weight evenly throughout the machine. This means that the machine never sinks on soft soils.

The tracks help to reduce the damage that the asphalt can produce, which also guarantees its use in the city. It is not necessary to use cranes since these machines can be driven directly from the warehouse to the workplace. We make it as easy as possible to adjust the tension in the tracks when necessary and the track components, in themselves, are replaceable.

GENERATOR IN

THE OWN MACHINE

YOU WILL NOT NEED EXTERNAL ENERGY SOURCES

All Tracstar have an on-board generator. They generate their own electricity and hydraulic energy, to give the operator all the comfort. This can be welding all day and does not have the need to carry extra machinery or generators separately.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| TracStar 28 Series 2 | TracStar 250 Series 2 | TracStar 412 Series 2 | TracStar 618 Series 2 | TracStar 500 Series 3 | TracStar 630 | TracStar 900 | TracStar 1200 | |

| Self-contained, self-propelled, all-terrain | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Removable 3- or 4-jaw carriage for close quarter use | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Dual Speed Tracks | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Patented Centerline Guidance System for equal distribution of force around the joint | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Serrated jaws and inserts keep pipe from slipping during fusion | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Thrust-bearing-equipped clamp knobs to minimize force required to clamp and round pipe | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Powerful hydraulic facer for facing the toughest pipe with ease | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Industry standard semi-automatic hydraulic control system | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| ISO-compliant industrial Teflon-coated heater plates | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Self-locking brakes | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| High-force cylinder machine available | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Medium-force cylinder machine available | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Low-force cylinder machine available | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| DataLogger® compatible | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| On-board generator for powering heater | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Advanced blade design for smooth face and long life | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Battery disconnect for easy lockout | ✓ | ✓ | ✓ | ✓ | ||||

| 8+ hours operational fuel tank capacity | ✓ | ✓ | ✓ | ✓ | ||||

| 11+ hours operational fuel tank capacity | ✓ | |||||||

| 12+ hours operational fuel tank capacity | ✓ | |||||||

| 17+ hours operational fuel tank capacity | ✓ | ✓ | ||||||

| Automated machine option | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Combination unit (CU) available for sidewall fusion | ✓ | ✓ | ||||||

| Dual hydraulic pipe lifts | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Hydraulic clamping available (standard on TracStar 500 Series 3, 630, 900, 1200) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Indexer-mounted, hydraulic pivoting heater and facer | ✓ | ✓ | ✓ | ✓ | ||||

| Fuel-saving auto throttle | ✓ | |||||||

| Heater and facer can be easily converted to top loading for confined spaces | ✓ | ✓ | ✓ | |||||

| Wireless Remote Control ensures safe efficient working environment and precise machine placement | ✓ | ✓ | ✓ | |||||

| Ergonomic operator platform | ✓ | |||||||

| Removable cowling design allows easy access for machine maintenance | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Remote engine stop/start | ✓ | |||||||

| Outriggers for machine stability and leveling | ✓ |