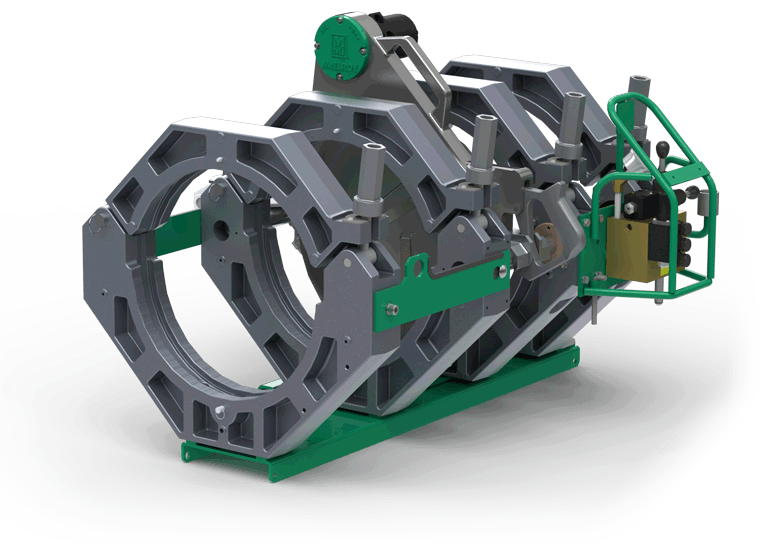

PIT BULL 26

2″ IPS – 6″ DIPS (63mm – 180mm)

The Pit Bull 26 comes with the already patented central guide system patented by McElroy, able to join all three, she and all kinds of accessories. The machine also has a semi-automatic locking cam that locks the mobile jaw in place during the entire welding cooling cycle. In addition this machine has an electric facer with a fast and efficient coating with an advanced knife design for smooth faces and a longer life.

PARTS & ACCESSORIES FOR THE PIT BULL 26

Highlighted substitution parts and accessories

Butt Fusion & Mitered Insert Sets

Surface hardened for longer life and are serrated for maximum grip.

6″ IPS Polyvalve Conversion Kit

Converts a standard 6″ Hot Tapping Tool to a 6″ Polyvalve Hot Tap Tool. Kit includes 3″ OD cutter.

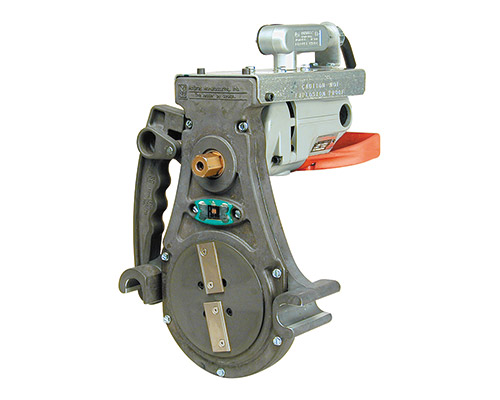

Hot Tap Tool

Tool for branch saddle drill. Very suitable for polyethylene pipes.

Low Profile Rollers

Low profile rollers

Manual Fusion Machine Stand

Expands to a comfortable operator height equal to our other pipe supports. Folds for easy storage and has wheels for easy transporting.

Pipe Support Stand

Height is adjustable to properly support, position and align pipe to be fused.

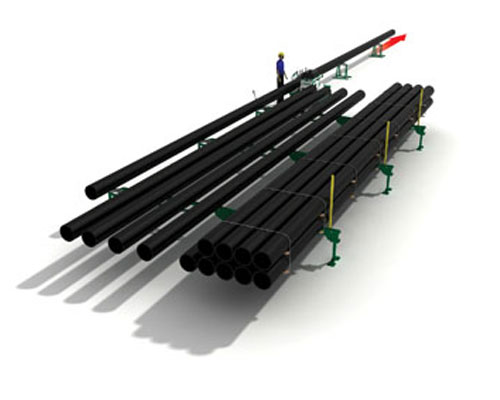

PolyHorse®

Pipe handling system that consists of a series of adjustable racks to store and help install pipe on the job site.

PolyPorter®

Aids in lifting pipe into the fusion machine and also performs as a pipe stand.

Pyrometer Gear Kit

For a more precise temperature measurement, our pyrometer gear kit will always give you the exact surface temperature.

Shipping Container

Shipping container for fusion machine, inserts and adapters.

Spare Facer

Powered blades keep the pipe edges clean and aligned.

Spare Facer Blades

Includes 4 blades, attaching screws and wrench.

Spare Facer Stand

Facer stand provides a convenient place to protect and store your facer out of the dirt and mud when fusing in-ditch.

Spare Heater Plate Kit

Anti-stick coated heater plates. Includes 2 plates and attaching screws.

Spare Heater Stand

Holds heater for easier carrying and protection. Heater bag helps the heater maintain a constant temperature.

Spare Heaters

Heaters have a microprocessor control and a dial thermometer to monitor temperature.

Test Caps

Quick and easy air pressure testing of polyethylene pipe.

Toolbox with Tray

For organizing your inserts and adapters for safe keeping.

Torque Wrench Adapter

Used to adapt a torque wrench when a specified interfacial pressure is required. Requires a ½» drive 100 ft. lb. 15″ torque wrench.

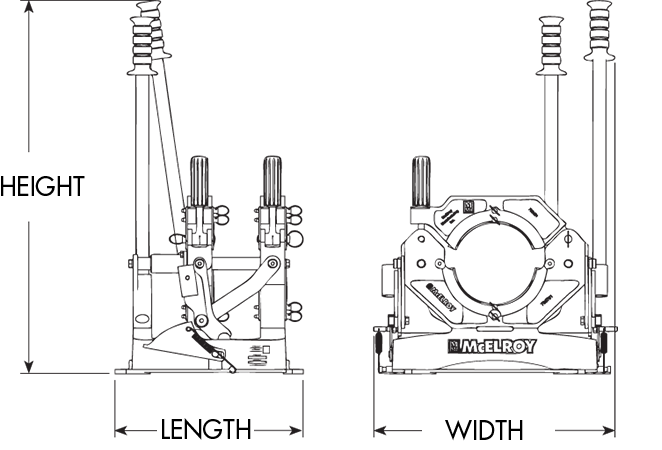

SPECIFICATIONS

| Pit Bull® 26 | |

| Carriage | 50 lbs (22.7 Kg) |

| Facer | 32 lbs (14.5 Kg) |

| Heater | 14 lbs (6.4 Kg) |

| Shipping Weight | 150 lbs (68 Kg) |

| Pit Bull® 26 | ||

| Machine | Shipping Container | |

| Length | 15.4″ (391 mm) | 27″ (686 mm) |

| Width | 19.7″ (500 mm) | 40″ (1016 mm) |

| Height | 30.4″ (773 mm) | 33″ (838 mm) |

IDEAL MACHINES DOR DICH WORK

The Pit Bull is our most battle machine, being one of the most resistant in our range. The car itself is capable of giving all the force necessary to merge small and medium diameter pipes when using wheels and vehicles mounted on tracks. Our Pitbull machine does not include the carriage, heater, insulated heater stand or hydraulic power unit (HPU). These are components that go separately and can be put into various arrangements to give maximum flexibility in more closed environments.

ROUGH &

TRUSTWORTHY

PERFECT FOR THE HARDEST AND MOST RESISTANT JOBS

Always get the best results with our machines. Still working all day at maximum performance, our Pit Bulls are capable of fusing pipes with outstanding results. They are also capable of giving the same power as any of our fusion or wheeled machines of the same size, being able to adapt comfortably in any vehicle with wheels or McElroy chains. All our machines have a system of jaws and inserts to prevent the pipe from sliding during the fusion.

SMALL

FOOTPRINT

CONSTRUCTED FOR REALLY SMALL SPACES

Our Pit Bulls are built to work in ditches and narrow spaces. All medium diameter machines can be adapted from a four-jaw to a three-jaw to provide an even more compact machine. To make our machines as light as possible and last, all our smaller models are made of hardened aluminum on its entire surface.

BEST QUALITY

AND CONSISTENCY

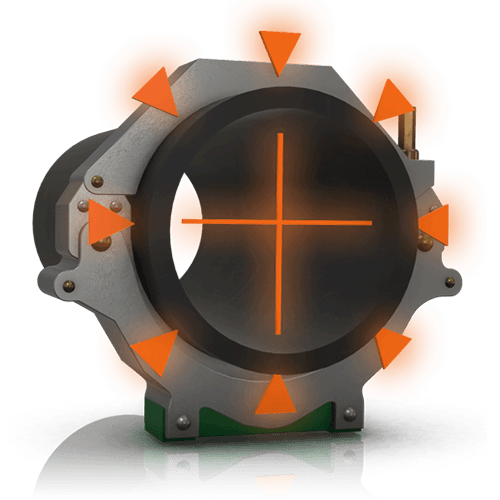

UNIFORM SUPPLY OF FOCES THANKS TO THE CENTERLINE GUIDANCE

All McElroy Machines have a Centerline Guidance a patented technology which creates an equal distribution of forces. This technology ensures that the center lines of the clamping jaws of the tubes are located in the same plane as the pipeline itself. As a result, we will obtain a high quality union provided by the equal force that is distributed by the center of the diameter of the tube during the fusion.

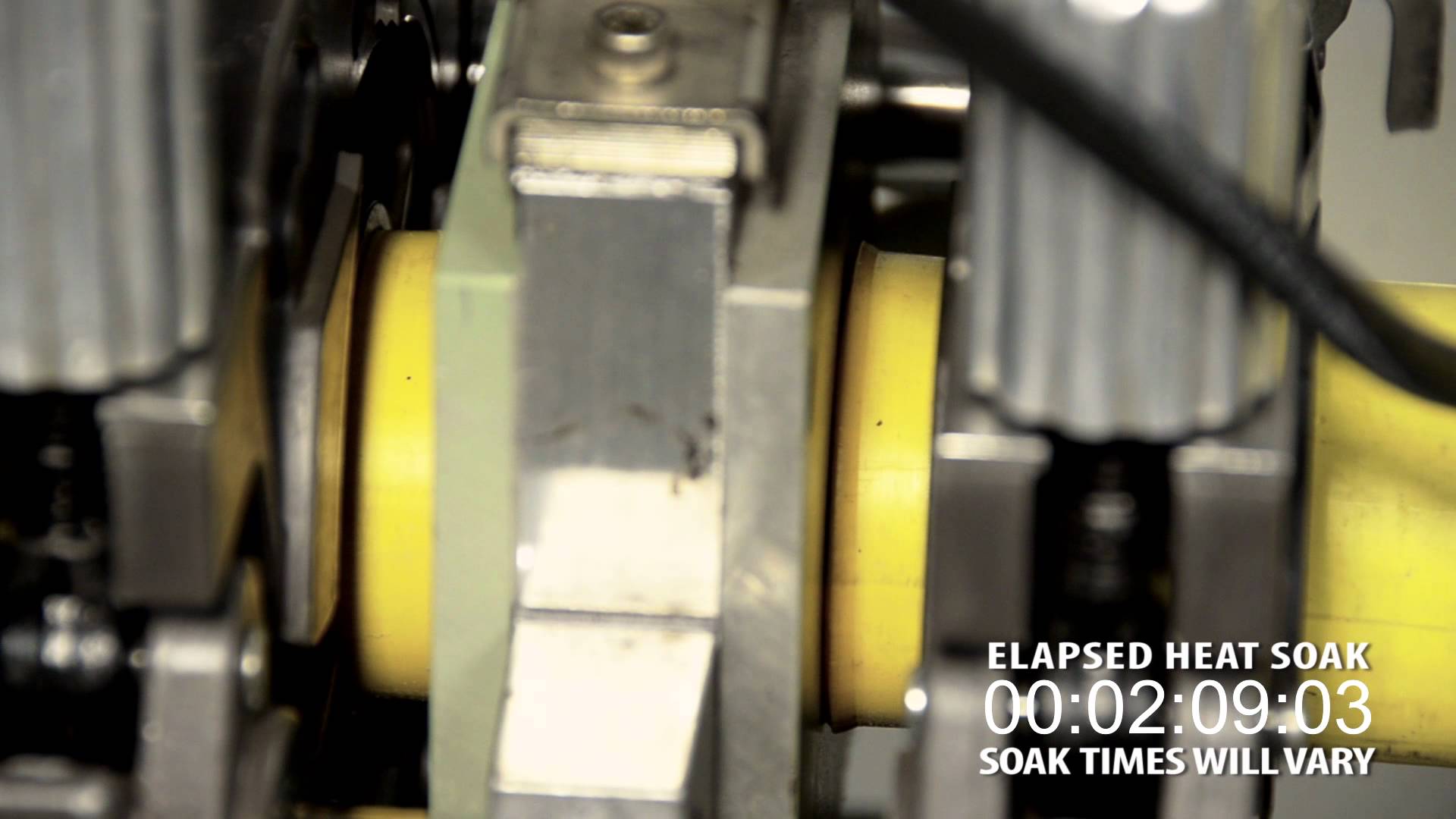

DATALOGGER®

COMPATIBLE*

THE EASIEST WAY TO RECORD & ANALYZE ALL YOUR FUSION JOINT DATA

All our medium diameter Pit Bull machines are compatible with McElroy DataLogger. This is a small handheld computer that is responsible for documenting and analyzing the key parameters that are happening throughout the merger process. Later all this data is used to verify that all steps and fusion procedures are adequate before installation. The joint DataLogger records can be stored and analyzed in Vault, our server on the Internet. This allows a better classification, faster and easier, a labeling and an exchange of joint records by machine, articulation, operator, device or work.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| Pit Bull 14 | Pit Bull 26 | Pit Bull 28 | Pit Bull 250 | Pit Bull 412 | Pit Bull 618 | |

| Patented Centerline Guidance System for equal distribution of force around the joint | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Semi-automatic locking cam system maintains force during cooling | ✓ | ✓ | ||||

| Hard-anodized aluminum wear surfaces for corrosion resistance | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Serrated jaws and inserts keep pipe from slipping during fusion | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Thrust-bearing-equipped clamp knobs to minimize force required to clamp and round pipe | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Advanced blade design for smooth face and long life | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Lightweight heater design with 45-degree handle to prevent overheating | ✓ | ✓ | ✓ | ✓ | ||

| Microprocessor-controlled heater | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| ISO-compliant industrial Teflon-coated heater plates | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Reversible jaws, clamp knobs, levers and facer allow operator to fuse from either side of the machine | ✓ | ✓ | ||||

| Removable 3- or 4-jaw carriage for close quarter use | ✓ | ✓ | ✓ | ✓ | ||

| High-force cylinder machine available | ✓ | ✓ | ✓ | ✓ | ||

| Medium-force cylinder machine available | ✓ | ✓ | ||||

| Low-force cylinder machine available | ✓ | ✓ | ✓ | ✓ | ||

| DataLogger® compatible | ✓ | ✓ | ✓ | ✓ | ||

| Powerful hydraulic facer for facing the toughest pipe | ✓ | ✓ | ✓ | ✓ | ||

| Industry standard semi-automatic hydraulic control system | ✓ | ✓ | ✓ | ✓ | ||

| Available in Combination Unit (CU) for sidewall fusion | ✓ | ✓ | ||||

| Hydraulic clamping available | ✓ | ✓ |