2CU

½» CTS – 2″ IPS (16mm – 60mm)

The 2CU is a combined unit that combines the side wall feature with the ability to fuse tubes. This machine has side wall clamps with bench screws. This allows the machine to stick to the center line of a tube for side fusion of ½ «to 2» service saddles, round base fork saddles and small thread T. The 2CU is equipped with chain lengths that can hold IPS pipes up to 8 . We also have longer chain lenghts if needed.

ACCESSORIES FOR THE 2LC

Highlighted substitution parts and accessories

Mittered & Butt Fusion Insert Sets

Can only be used for one size pipes less than 2” IPS. Inserts are serrated to assure a better grip and also hardened to resist more.

Polyvalve for 6” IPS Conversion Kit Set

Kit to convert a 6” standard hot tapping tool into a 6” polyvalve hot tap tool. This kit includes a cutter for 3” OD.

Heat Shield Protector

This heat shield is ideal when welding two plastic materials with different melting rates. The shield will protect the material that melts faster from over melting.

Hot Tap Tool

Tool for branch saddle drill. Very suitable for polyethylene pipes.

Metal storage box for inserts and adapters

Perfect metallic box to organize and store your inserts and adapters.

Manual Welding Stand

Adapts to the height of each operator. It has wheels and folds, which facilitates its transport and storage.

Multi-Mc Heaters

Our heaters have a dial thermometer and microprocessor for total temperature control. This accessory requires adapters for its use.

Pyrometer Gear Kit

For a more precise temperature measurement, our pyrometer gear kit will always give you the exact surface temperature.

Screwdriver Gear Kit

Extra gear kit with screwdriver, insert screws and wire brush ideal for cleaning your inserts and serrated jaws.

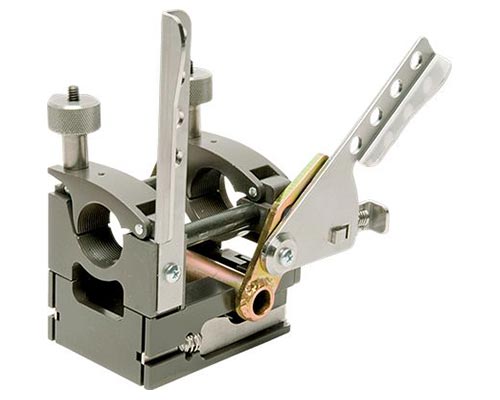

Spare Facer

Spare facer ideal for face pipe ends when they have to be welded.

Spare Facer Blades

Spare facer blades.

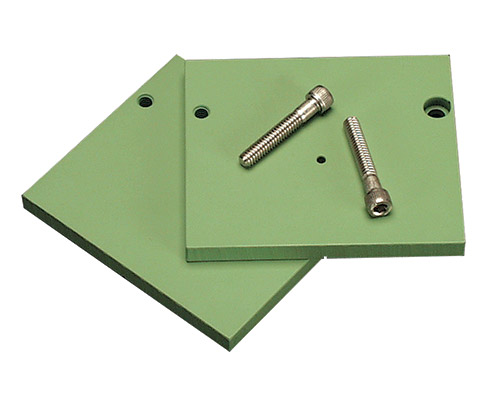

Spare Heater Plate Kit

Our spare hater plates have an anti-sticking coating which are required for butt fusion.

Spare heater bag and stand kit

Protects and makes easier to transport your facer and heater. Heater bag will provide a constant temperature when welding.

2LC Storage Box

Big box to carry and store your fusion machines, adapters and inserts.

Testing Caps

Polyethylene caps tubes for a quick and easy air pressure testing.

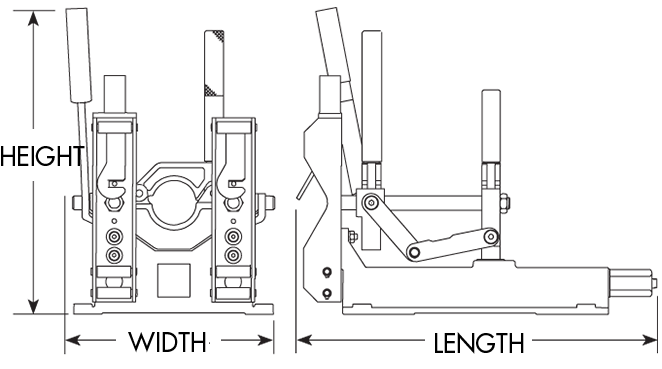

SPECIFICATIONS

| 2CU | |

| Machine | 28 lbs (12.7 Kg) |

| Heater | 7.24 lbs (3.28 Kg) |

| Facer | 7.9 lbs (3.54 Kg) |

| Shipping Weight | 58 lbs (26.3 Kg) |

| 2CU | ||

| Machine | Shipping Container | |

| Length | 11″ (279 mm) | 28″ (711 mm) |

| Width | 20″ (508 mm) | 16″ (406 mm) |

| Height | 16″ (406 mm) | 20″ (508 mm) |

MANUAL

JUST ONE OPERATOR: THE EASIEST WAY FOR FUSION WELDING

Manual fusion machines give you all the muscle needed to do precise fusions on the hardest conditions all day long. Resistant and trustworthy, this fusion welding machines are compact, lightweight and only precise of one operator to be handled. Our precise engineering machines provide a total integrity with a really low maintenance.

BEST QUALITY

& CONSISTENCY

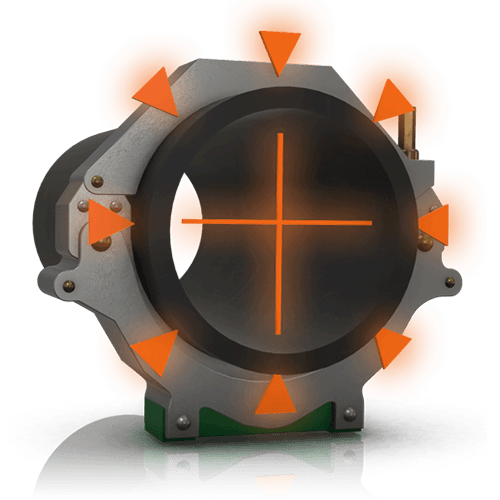

UNIFORM SUPPLY OF FOCES THANKS TO THE CENTERLINE GUIDANCE

All McElroy Machines have a Centerline Guidance a patented technology which creates an equal distribution of forces. This technology ensures that the center lines of the clamping jaws of the tubes are located in the same plane as the pipeline itself. As a result, we will obtain a high quality union provided by the equal force that is distributed by the center of the diameter of the tube during the fusion.

PLASTIC PIPE WELDING

HAS SEVERAL MACHINE OPTIONS

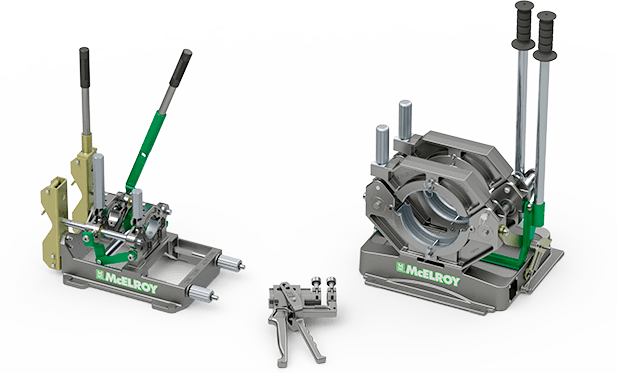

BUTT FUSION CHOICES FOR ½» CTS TO 6″ DIPS PIPE

In Plastic Pipe Welding we have a wide variety of small and light machines for butt fusion tubes ranging from 1/2 «CTS to 6» DIPS (16mm to 180mm). With only one machine you can weld tubes of all sizes, since all our individual machines cover the entire range of existing pipe diameters.

FUSIONS AND

WORKS

MACHINES DESIGNED SPECIFICALLY FOR A GOOD EASE OF USE

Our machines are so light and compact that you will not have any problem using them wherever you want. On the ground or inside the trench, they will always yield the most. All our machines are coated with hardened aluminum at the surface, which provides them with an extra resistance to the most adverse conditions and the most extreme climates. For manual fusion, our machines have a narrow clamp that will help you align the pipes when welding.

LEADERS OF THE

PLASTIC PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| Mini-Mc® | 1LC | 2LC | 2CU | Pit Bull 14 | Pit Bull 26 | |

| Hand-operated | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Thermostatically-controlled heater to provide constant fusion temperature | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| ISO-compliant industrial Teflon-coated heater plates | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Patented Centerline Guidance System for equal distribution of force around the joint | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Hard-anodized aluminum wear surfaces for corrosion resistance | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Thrust-bearing-equipped clamp knobs to minimize force required to clamp and round pipe | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Narrow clamp design for precise pipe alignment | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Narrow clamp design for precise pipe alignment | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Serrated jaws and inserts keep pipe from slipping during fusion | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Conventional facer design features ball-bearing construction and gear drive for long life | ✓ | ✓ | ✓ | |||

| Locking cam to maintain force during the cooling cycle | ✓ | ✓ | ✓ | ✓ | ||

| Compact and Durable | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Sidewall capabilities for 1/2″ to 2″ fittings | ✓ | ✓ | ✓ | ✓ | ✓ |