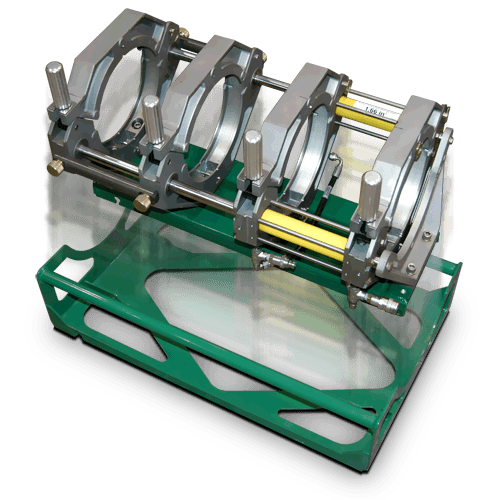

DYNAMC 250

63mm – 250mm (2” IPS – 8” DIPS)

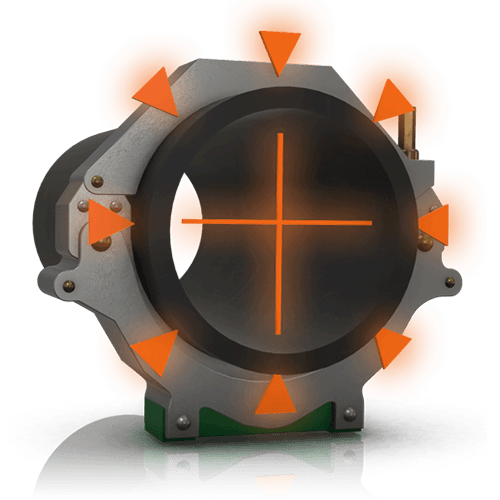

Maximum power in the smallest package. This is the line of DynaMC of 250. It is a machine that has been built especially for the fusion of pipes in pits. These machines have all the patented features of the McElroy brand in a small unit for use in smaller environments.

The DynaMc 250 is fully fused with a hand pump, while the DynaMc 250 EP is powered by the Hydraulic Power Unit (HPU). Both are available as 2 or 4 jaw models. There is also an automatic unit of 4-jaw.

PARTS & ACCESSORIES FOR THE DYNAMC 28

Highlighted substitution parts and accessories

Butt Fusion & Mitered Insert Sets

Surface hardened for longer life and are serrated for maximum grip.

DataLogger® 6

Collect and analysis of data on all your fusions

6″ IPS Polyvalve Conversion Kit

Converts a standard 6″ Hot Tapping Tool to a 6″ Polyvalve Hot Tap Tool. Kit includes 3″ OD cutter.

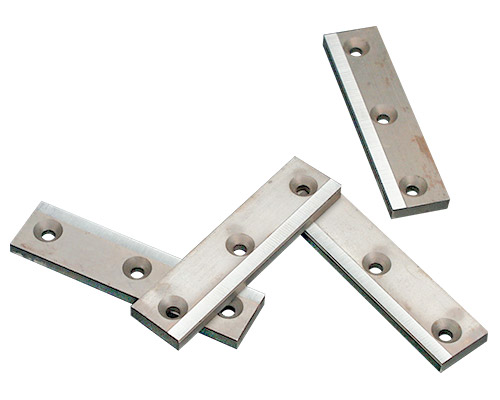

Blade set

Spare 4 set facer blades, extended life facer blade set and cardibe blades for abrasive materials.

DynaMc HPU

Hydraulic Power Unit. HPU 120V, 60Hz, 1Ph. HPU 220V-240V, 50/60Hz, 1Ph

Facer Stand

Facer stand provides a convenient place to protect and store your facer out of the dirt and mud.

Heat Shield

For fusing two materials with different melt rates. Shields the faster melt rate materials from over melting.

Heater Caddy

The Heater Caddy allows you to use the machine to easily carry the heater with the stand from joint to joint. Retrofit Kit for TracStar 28/250 machines built before 9/2010. Allows the heater and heater bag frame to attach to a TracStar.

Heaters

Heaters have a microprocessor control and a dial thermometer to monitor temperature. 220-240V, 50/60Hz, 1Ph Heater. 100-120V, 50/60Hz, 1Ph Heater.

Hot Tap Tool

Branch saddle tapping tool for polyethylene pipe.

Low Profile Rollers

Low profile rollers.

Pyrometer Kit

Pryometer kit for accurately checking surface temperatures of heater. Measures surface temperature of heater.

Self-Centering Stub End Holder

Self-centering stub end holder to hold stub end for butt fusion.

Spare Heater Plate Kit

Heater plates have an anti-stick coating and are required for butt fusion.

Test Caps

Quick and easy air pressure testing of polyethylene pipe.

Toolbox with Tray

For organizing your inserts and adapters for safe keeping. For organizing your inserts and adapters for safe keeping.

SPECIFICATIONS

| DynaMc® Hand Pump | DynaMc® Electric Pump | DynaMc® Auto | |

| 4-Jaw | 155 lbs (70 Kg) | 125 lbs (57 Kg) | 54 Kg (119 lbs) |

| 2-Jaw | 108 lbs (49 Kg) | 78 lbs (36 Kg) | N/A |

| Facer | 39 lbs (17.7 Kg) | 39 lbs (17.7 Kg) | 21.3 Kg (47 lbs) |

| Heater | 21 lbs (9.5 Kg) | 21 lbs (9.5 Kg) | 19.5 Kg (43 lbs) |

| HPU (Hydraulic Power Unit) | N/A | 115 lbs (52.1 Kg) | 75.3 Kg (166 lbs) |

| 4-Jaw Shipping Container | 285 lbs (130 Kg) | 490 lbs (222.3 Kg) | 236 Kg (520 lbs) |

| 2-Jaw Shipping Container | 220 lbs (100 Kg) | N/A | N/A |

| DynaMc® Hand Pump | DynaMc® Electric Pump | DynaMc® Auto | |

| System Pressure | 1,500 PSI (103 BAR) Max | 1,500 PSI (103 BAR) Max | 83 BAR (1,200 PSI) Max |

| DynaMc® Hand Pump | DynaMc® Electric Pump | DynaMc® Auto | |

| Frame | Welded aluminum construction | Welded aluminum construction | Welded aluminum construction |

| DynaMc® Hand Pump | DynaMc® Electric Pump | DynaMc® Auto | |

| Heater Power | 3000 Watt @ 240V / 1750 Watt @ 120V | 3000 Watt @ 240V / 1750 Watt @ 120V | 3000 Watt |

| Facer Power | 1.6 HP, 10 Amp @ 120V / 5 Amp @ 240V | 1.6 HP, 10 Amp @ 120V / 5 Amp @ 240V | Hydraulic |

| HPU (Hydraulic Power Unit) | N/A | 2.2 HP, 14 Amp @ 120V / 7 Amp @ 240V | 4.0 HP, 28 Amp @ 110V / 14 Amp @ 220V |

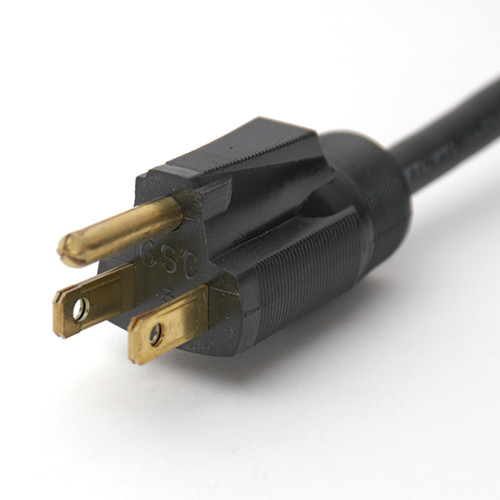

| Facer Plug Type | 120V – A | 120V – A | N/A |

| 240V – M | 240V – M | N/A | |

| Heater Plug Type | C | C | N |

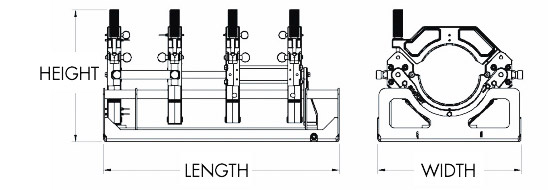

| DynaMc® Hand Pump | DynaMc® Electric Pump | DynaMc® DynaMc® Auto | DynaMc® Shipping Container | |||||

| 2-Jaw | 4-Jaw | 2-Jaw | 4-Jaw | HPU | Machine | HPU | ||

| Length | 26″ (660 mm) | 34″ (864 mm) | 26″ (660 mm) | 34″ (864 mm) | 24.5″ (622 mm) | 864 mm (34″) | 597 mm (23.5″) | 48″ (1219 mm) |

| Width | 26″ (660 mm) | 26″ (660 mm) | 21″ (533 mm) | 21″ (533 mm) | 11″ (279 mm) | 533 mm (21″) | 559 mm (22″) | 40″ (1016 mm) |

| Height | 23.5″ (597 mm) | 23.5″ (597 mm) | 19″ (483 mm) | 19″ (483 mm) | 21.5″ (546 mm) | 483 mm (19″) | 406 mm (16″) | 33″ (838 mm) |

GREAT POWER IN A SMALL MACHINE

Our DynaMc offer great power in a very small package. They are ideal machines for the fusion butt in really reduced spaces. Despite their small size the DynaMc offer the best features; Robustness and strength patented by McElroy. Available in units of 2 and 4 jaws. These jaws are easily separated from the base in order to further reduce the footprint of the machine. It is available in three ranges of tube sizes. From the smallest of 2 «(63mm) to 12» (340mm).

COMPACT AND

MODULAR MACHINES

PERFECT FOR CLOSE-QUARTER FUSION

Our DynaMc consists of a trolley, a restraint support, a restrainer, a heater and an insulator heater support. All of them can be moved and placed comfortably to give maximum flexibility in the smallest work environments. All the components of this machine are specially built to offer a compact design without losing any kind of limitation. It is available in configurations of 2 and 4 jaws. In the 4 jaw units, the full length guide rod and the third single movable jaw allow working in the vicinity of the cardinal points and the tees without the removal of the outer jaw.

LOT OF

MACHINE OPTIONS

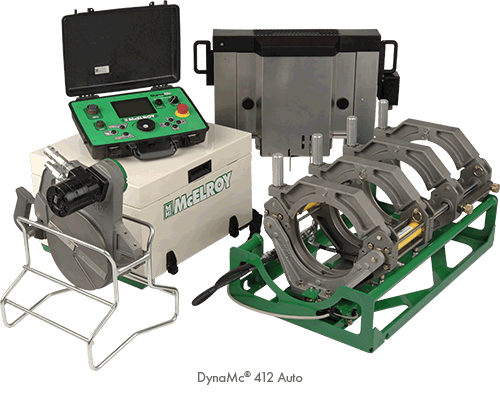

ALL KIND OF MODELS AVAILABLE: ELECTRIC, HAND AND AUTOMATIC PUMP MODELS

We have several models. The HP DynaMc (hand pump) welds the pipes to butt with the hand pumps. The DynaMc EP (electric pump) works with a common hydraulic unit (HPU). This same HPU can be used with many other DynaMc machines. The HPU also uses a hydraulic accumulator to maintain fusion pressures and reduce energy consumption. The DynaMc Autos offer a powerful combination of features and operate within the PL2-3 gas industry specification and water industry specification 4-32-08, as well as other specifications.

DATALOGGER®

COMPATIBLE*

THE EASIEST WAY TO RECORD & ANALYZE ALL YOUR FUSION JOINT DATA

All our DynaMc machines are compatible with McElroy DataLogger. This is a small handheld computer that is responsible for documenting and analyzing the key parameters that are happening throughout the merger process. Later all this data is used to verify that all steps and fusion procedures are adequate before installation. The joint DataLogger records can be stored and analyzed in Vault, our server on the Internet. This allows a better classification, faster and easier, a labeling and an exchange of joint records by machine, articulation, operator, device or work.

BEST QUALITY

AND CONSISTENCY

UNIFORM SUPPLY OF FOCES THANKS TO THE CENTERLINE GUIDANCE

All McElroy Machines have a Centerline Guidance a patented technology which creates an equal distribution of forces. This technology ensures that the center lines of the clamping jaws of the tubes are located in the same plane as the pipeline itself. As a result, we will obtain a high quality union provided by the equal force that is distributed by the center of the diameter of the tube during the fusion.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| DynaMc HP | DynaMc EP & HPU | DynaMc Auto | |

| Patented Centerline Guidance System for equal distribution of force around the joint | ✓ | ✓ | ✓ |

| On four-jaw units, the full-length guide rod and unique moveable third jaw allow work in close proximity to ells and tees without the removal of the outer jaw | ✓ | ✓ | |

| Serrated jaws and inserts keep pipe from slipping during fusion process | ✓ | ✓ | ✓ |

| Detachable easy-lift cradle for improved maneuverability to and from worksite | ✓ | ✓ | ✓ |

| Utilizes a hydraulic accumulator to maintain fusion pressure and reduce power consumption | ✓ | ||

| ISO-compliant industrial Teflon-coated heater plates | ✓ | ✓ | ✓ |

| Powerful electric facer that can be loaded from either side of the carriage | ✓ | ✓ | ✓ |

| Double-action hand pump and high-velocity cylinders create fast carriage speeds during fusion processes | ✓ | ||

| 2-jaw machine availability | ✓ | ✓ | |

| DataLogger® compatible | ✓ | ✓ | |

| Features a common Electric Pump that powers a variety of fusion machines | ✓ | ||

| USB port for downloading fusion reports and uploading firmware | ✓ | ||

| Weather-resistant enclosure for control unit | ✓ | ||

| Built-in magnetic strips allow attachment of control unit to power unit | ✓ |