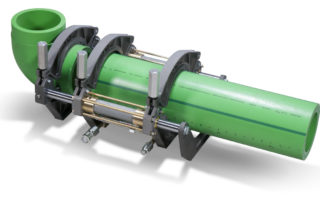

ACROBAT™ 160

63mm – 160mm (2″ – 6″)

This is a low strength fusion machine ideal for joining fuses in small workspaces. Its small design and low weight make it the perfect machine for aerial mergers in small spaces and on the ground.

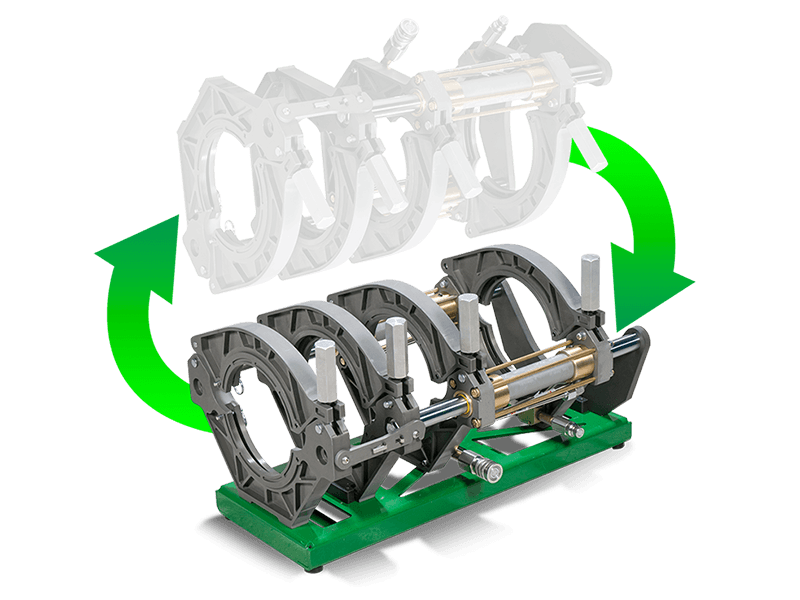

Like other of our machines, the Acrobat 160 allows to configure from 4 jaws to 3 without using any type of tools to work in even narrower and smaller spaces.

PARTS & ACCESSORIES FOR ACROBAT™ 160

Highlighted substitution parts and accessories

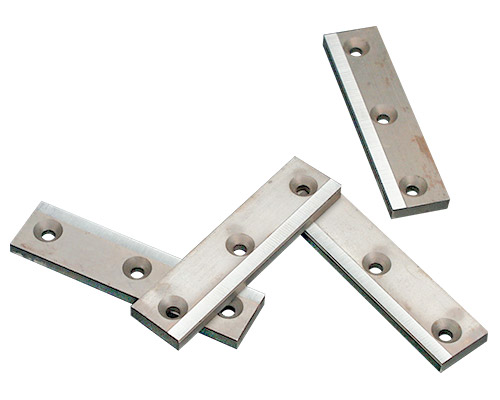

Butt Fusion & Mitered Insert Sets

Surface hardened for longer life and are serrated for maximum grip.

Acrobat HPU

Hydraulic Power Unit. 120V, 50/60Hz, 1Ph.

DynaMc HPU

Hydraulic Power Unit. HPU 120V, 60Hz, 1Ph. HPU 220V-240V, 50/60Hz, 1Ph.

Low Profile Rollers

Low profile rollers.

Manual Fusion Machine Stand

Expands to a comfortable operator height equal to our other pipe supports. Folds for easy storage and has wheels for easy transporting.

Pipe Support Stand

Height is adjustable to properly support, position and align pipe to be fused.

PolyPorter®

Aids in lifting pipe into the fusion machine and also performs as a pipe stand.

Premium Shipping Container

Protects and transports machine, HPU, heater and facer. Acrobat 160 Premium Shipping Container.

Pyrometer Kit

Pryometer kit for accurately checking surface temperatures of heater. Measures surface temperature of heater.

Rotary Pipe Cutters

Easily cut pipe up to 125mm. 63mm-125mm rotary pipe cutter.

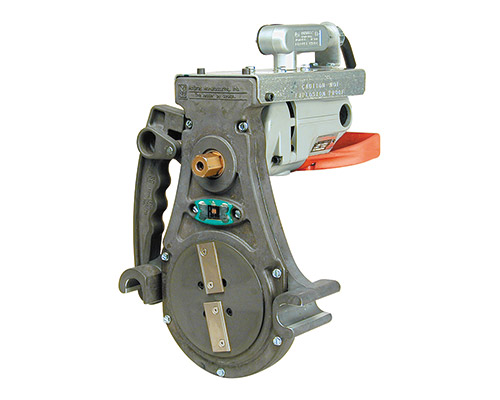

Spare Facer

Powered blades keep the pipe edges clean and aligned. 100-120V, 50/60Hz, 1Ph. 220-240V facer assembly.

Spare Facer Blade Set

Spare facer blades.

Spare Facer Stand

Facer stand provides a convenient place to protect and store your facer out of the dirt and mud when fusing in-ditch.

Spare Heater Plate Kit

Heater plates have an anti-stick coating and are required for butt fusion. Set of 2 plates with anti-stick coating required for butt fusion. Kit includes attaching screws and wrench.

Spare Heater Stand

Holds heater for easier carrying and protection. Heater bag helps the heater maintain a constant temperature.

Spare Heaters

Heaters have a microprocessor control and a dial thermometer to monitor temperature. 100-120V, 50/60Hz, 100 Watt, 1Ph. 220-240V, 50/60Hz, 100 Watt, 1Ph.

SPECIFICATIONS

| Acrobat™ 160 | |

| 4-Jaw Carriage | 40 lbs (18.1 Kg) |

| 3-Jaw Carriage | 29 lbs (13.2 Kg) |

| Facer | 35lbs (15.9Kg) |

| Heater | 14lbs (6.4Kg) |

| Hydraulic Power Unit (HPU) | 56 lbs (25.4 Kg) |

| Shipping Weight | 350 lbs (158.8 Kg) |

| Acrobat™ 160 | |

| Maximum Gauge Pressure | 400 PSI (27.6 BAR) |

| Acrobat™ 160 | |

| Heater | 1.2 kW |

| Facer Power | 120V – .9 kVA / .7 kW 240V – 1.2 kVA / 1 kW |

| Input Voltage Requirements | 120V – 50/60Hz, 1 Ph 240V – 50/60Hz, 1 Ph |

| Hydraulic Power Unit (HPU) | 120V – .3 HP/ 5.9 Amp 240V – .3 HP/ 2.4 Amp |

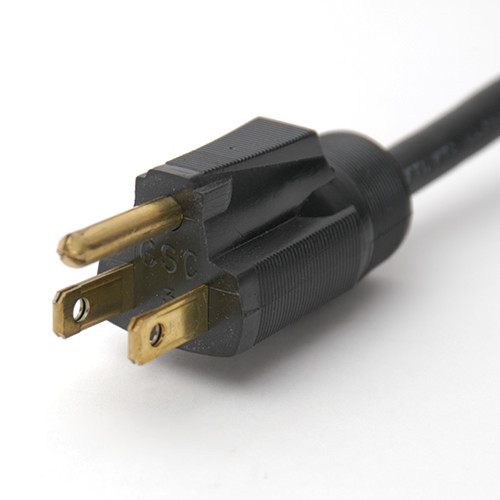

| Plug Type | 120V-120V – Nema 5-15 240V – CEE 7/7 |

| Acrobat™ 160 | |

| Frame | Welded aluminum construction |

| Acrobat™ 160 | HPU | Shipping Container | ||

| 4-Jaw Carriage | 3-Jaw Carriage | |||

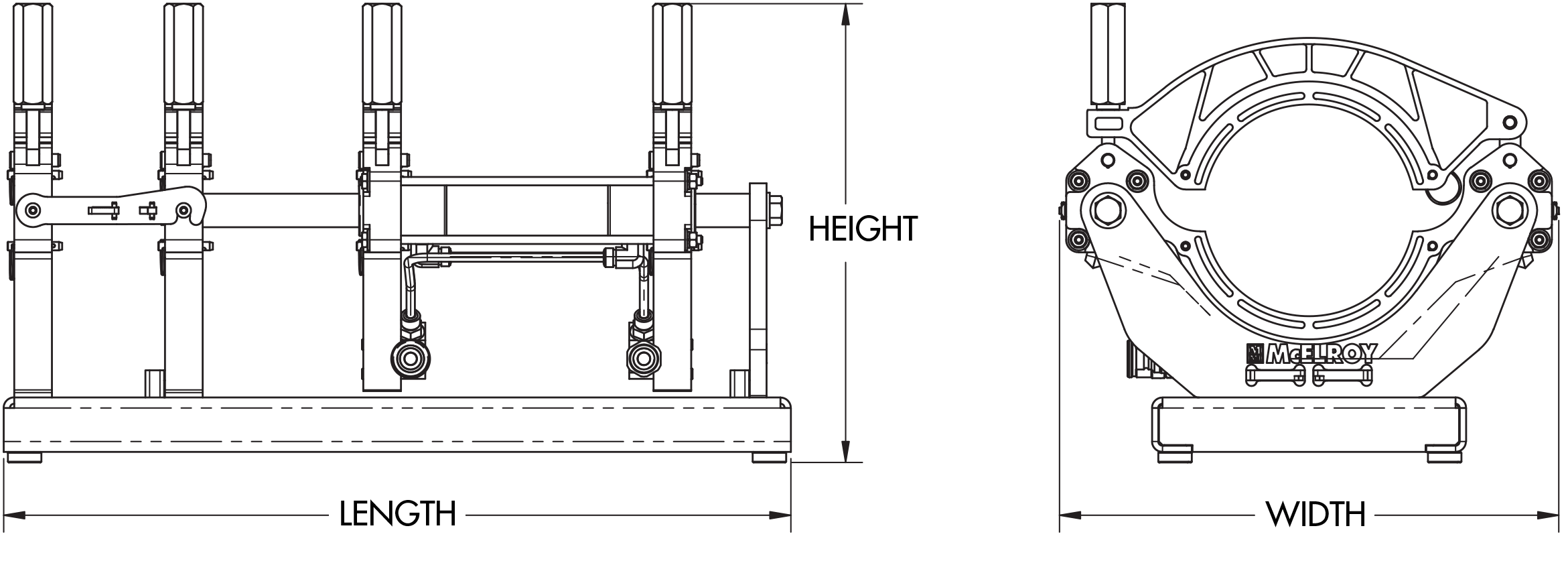

| Length | 23.5″ (597 mm) | 19″ (483 mm) | 22.1″ (562 mm) | 28″ (711 mm) |

| Width | 15″ (381 mm) | 15″ (381 mm) | 13.2″ (335mm) | 40″ (1,016 mm) |

| Height | 14″ (356 mm) | 12″ (305 mm) | 19″ (482.6 mm) | 40″ (1,016 mm) |

ADAPTABLE AND FLEXIBLE TO COMPLY WITH THE REQUIREMENTS OF ANY WORK

These machines offer the best features for butt welding of polypropylene pipes in more advanced mechanical and commercial HVAC plumbing applications. The Acrobat fusion machines are simple to operate, have a compact design and are very light. You can weld pipes on ceilings, on walls or on the floor. We have two models that can weld pipes of sizes between 63mm and 315mm (2 «to 12») of polypropylene.

SMALL AND VERY

LIGHT MACHINES

This machine has been specially built to have a small size and a light weight. In this way we managed to simplify the mergers on the head. The Acrobat model has a modular hydraulic power unit that consumes much less power and also makes the machine lighter. This makes the transport of all our Acrobat machines at work easier.

MORE VERSATILE

HYDRAULIC POWER

VERSATILITY IN THE POWER AND CART CONFIGURATIONS TO SATISFY THE REQUIREMENTS OF EACH PROJECT

In order to satisfy all the desired pressure of the system in the construction projects, our Acrobat machines are compatible with two hydraulic power units. The carriage pressure can be configured in two ways: Low force, in the event that we are going to merge with slow entrainment or in thin-walled tubes. And high force, for those cases in which we are going to merge with high drag and vertical applications. In both options the operator will be able to define the pressures of countersigned, heating and fusion.

MAKES MERGERS IN

ANY TYPE OF ORIENTATION

VERTICAL INSTALLATIONS, ON THE HEAD AND MUCH MORE

All our Acrobat machines are adapted to any type of situation and are capable of welding on the head, vertically or horizontally. It has narrow jaws that achieve fusions in several flanges and connectors. The Acrobat 250 and 315 models have a light heater system and blocking of the guide bar. That eliminates the need to hold the heater in place in the head-on fusions.

CONVERT THE ACROBAT IN A SMALLER 3-CLUTCH TRUCK WITHOUT TOOLS

Transforms the car from 4 to 3 jaws by disassembling it from its base without the need for extra tools. In this way you will get a smaller machine for narrow spaces. Both the countersigned and the heater can be loaded above or below the carriage with this configuration. In this way the operator can work more comfortably and flexibly in any work situation.

DATALOGGER®

COMPATIBLE*

THE EASIEST WAY TO RECORD & ANALYZE ALL YOUR FUSION JOINT DATA

All Acrobat machines are compatible with McElroy DataLogger. This is a small handheld computer that is responsible for documenting and analyzing the key parameters that are happening throughout the merger process. Later all this data is used to verify that all steps and fusion procedures are adequate before installation. The joint DataLogger records can be stored and analyzed in Vault, our server on the Internet. This allows a better classification, faster and easier, a labeling and an exchange of joint records by machine, articulation, operator, device or work.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty

ADITIONAL FEATURES

| Acrobat 160 | Acrobat 250 | Acrobat 315 | |

| Small footprint, lightweight | ✓ | ✓ | ✓ |

| Tool-less conversion from 4-jaw to 3-jaw carriage for tight work spaces | ✓ | ✓ | ✓ |

| Narrow jaws allow fusions for flanges to outlet branch of tees and most fittings | ✓ | ✓ | ✓ |

| Hard anodized aluminum wear surfaces for corrosion resistance | ✓ | ✓ | ✓ |

| DataLogger® compatible | ✓ | ✓ | ✓ |

| Single insert design | ✓ | ||

| Removable upper jaws | ✓ | ✓ | ✓ |

| Ergonomic heater handlebar design✓ | ✓ | ✓ | |

| Lightweight heater and guide rod latching system eliminates the need to hold the heater in place during overhead fusions | ✓ | ✓ | |

| Low-power consumption | ✓ | ✓ | ✓ |

| Open-frame HPU design offers easy access for maintenance | ✓ | ✓ | ✓ |

| Low- or high-force cylinders available for versatility | ✓ | ✓ | |

| Compatible with Acrobat and DynaMc® HPUs to meet maximum system pressure desired | ✓ | ✓ | |

| Facer with inline motor and gear reduction for lightweight, compact assembly; squeeze trigger makes locking and unlocking from the carriage easier | ✓ |