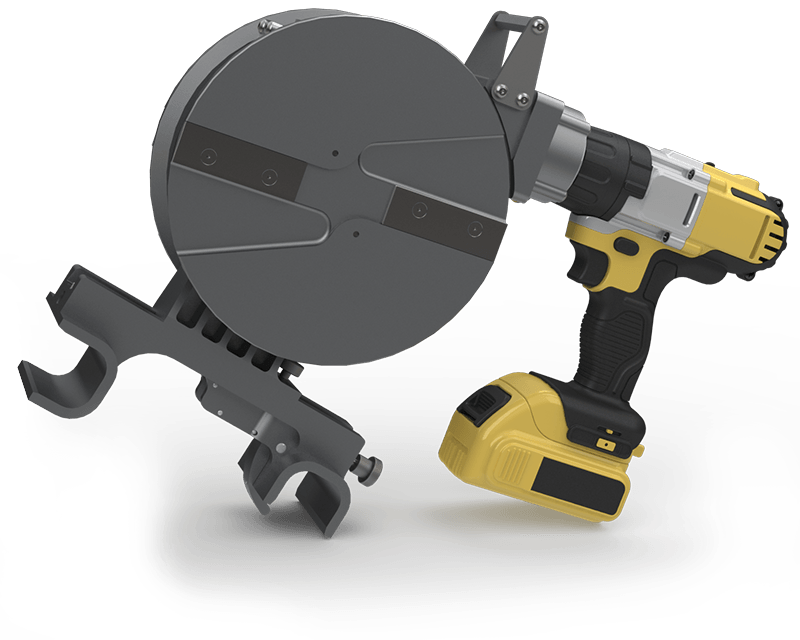

DICOVER OUR NEW SPECIALIZED MACHINE FOR SOCKET, MITER AND BUTT FUSION

The McElroy Polygon is a new machine that will give any installer complete flexibility when it comes to butt and miter fusions of all kinds. This new machine is the first of its kind, the manuals, which is compatible with the DataLogger®. With it you can perform butt and miter fusions from angles from 0º to 45º and also an additional capacity to perform socket fusions. It is a perfect prefabrication machine for workplaces with polypropylene pipes from 63mm to 160mm are handled. The McElroy Polygon is a three in one tool, with the simplest design and a very lightweight.

FUSES MITER ANGLES AT YOUR WORKPLACE

The Polygon machine has several miter options specially designed to perform work on complex mechanical pipe installations and also for modifications in which installation technicians must navigate around various obstructions in buildings and works. You will save on time and costs by buying and waiting for molded or manufactured accessories to be made since Polygon is capable of performing miter fusions in the field.

JAWS THAT PIVOT

This machine has a quick-clamping system which allows jaws pivot to move in any direction and makes the set-up for the machine much easier and faster. For any type of butt or miter fusion, you can lock up the jaws in any angle from 0º to 45º. The Polygon machine has also external jaws which can be removed easily if you need to do fusions in tighter work spaces. We also have the option to exchange the jaws for an optional Spider 125 adapter Kit for socket fusion.

DATALOGGER® COMPATIBLE*

THE EASIEST WAY TO RECORD & ANALYZE ALL YOUR FUSION JOINT DATA

All Acrobat machines are compatible with McElroy DataLogger. This is a small handheld computer that is responsible for documenting and analyzing the key parameters that are happening throughout the merger process. Later all this data is used to verify that all steps and fusion procedures are adequate before installation. The joint DataLogger records can be stored and analyzed in Vault, our server on the Internet. This allows a better classification, faster and easier, a labeling and an exchange of joint records by machine, articulation, operator, device or work.

REQUIRES VERY SMALL POWER

The Polygon machine has a manual fusion power carriage and also a battery-operated drill in order to power up the facer. The only power source needed will be for the 1,600W heater. That’s the reason this machine simplifies working space and also reduces considerably the extra amount of power equipment usually needed.

LEADERS OF THE

PLASTIC PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| Hornet | |

| Produces miter, butt and socket fusion joints | ✓ |

| Quick-clamp, pivoting jaws for faster, easier setup | ✓ |

| Quick open/close, non-back-drivable wheel drive for smooth jaw movement | ✓ |

| Side-positioned wheel drive | ✓ |

| Power required only for the heater; battery-operated drill powers the facer | ✓ |

| The first manual machine with DataLogger capability to assure quality fusion joints | ✓ |

| Sturdy travel case for easy transport of entire machine and accessories | ✓ |

| Easy-to-view pressure gauge | ✓ |