MEGAMC 1236 SERIES 2

12″ IPS – 36″ OD (340mm – 900mm)

Whether the fusion takes place inside the trench or above the ground, the quality of the fusion will always be the same. The car with which the MegaMc 1236 comes has hydraulic and electrical connectors improved and interchangeable with our machines Tracstar 630 and 900 series 2, which allows to mount the car in vehicles or tracked vehicles.

The trolley comes with 4 jaws that can be modified to 3 jaws for a better job in ditches. Both the heater and the restrainer can be loaded on top of the machine to save space. The MegaMc 1236 Series 2 has hydraulic power assists for all its welding functions such as the operation of jaws, pipe lifts, heater and facer. With this machine you will be able to perform any type of butt fusion without special supports or the elimination of the outer jaw. Mitered inserts are available for manufacturing ells.

PARTS & ACCESSORIES FOR THE MEGAMC 1236

Highlighted substitution parts and accessories

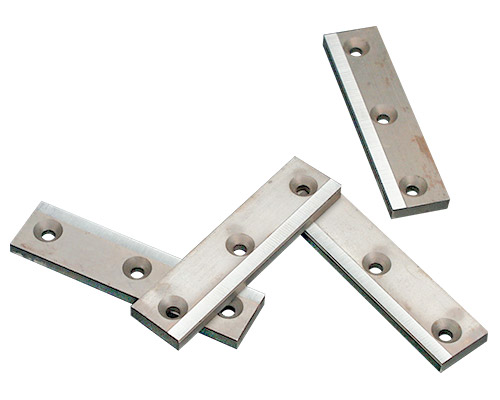

Butt Fusion & Mitered Insert Sets

Surface hardened for longer life and are serrated for maximum grip.

DataLogger® 6

Collect and analysis of data on all your fusions

Blade set

Spare facer blades.

Heater/Facer Stand

Trim the bead created during the fusion process.

Hydraulic Pipe Stand

Adjustable pipe stand to properly support, position, and align pipe to be fused. 12″/18″ Pipe Stand. 12″/18″ Pipe Stand with Manual Height Adjustment. 12″/18″ Pipe Stand with Hydraulic Height Adjustment.

In-Ditch Extension Kit

Set of 40′ hydraulic extension hoses and cable. This kit is required for in-ditch fusion.

In-Ditch Heater/Facer Stand

Heater/Facer stand recommended for tight in-ditch installations where top loading of the heater and facer is necessary.

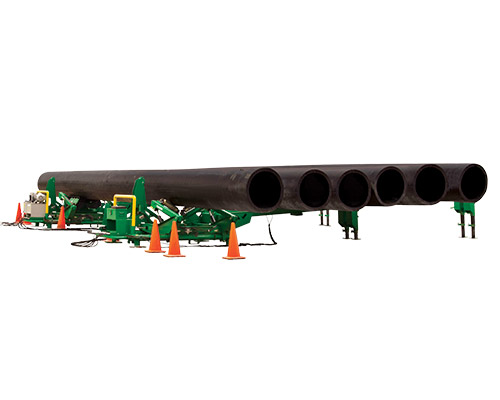

MegaMc® Pipe Stand

Powered pipe stand with lateral and vertical movement. MegaMc 8-36 Pipe Stand (gas). MegaMc 8-36 Pipe Stand (diesel).

MegaMc® PolyHorse®

Pipe Handling System. Pipe-handling system for 20″ to 48″ pipe.

MegaMc® Rollers

Low Profile Rollers

Pyrometer Kit

Pryometer kit for accurately checking surface temperatures of heater. Measures surface temperature of heater.

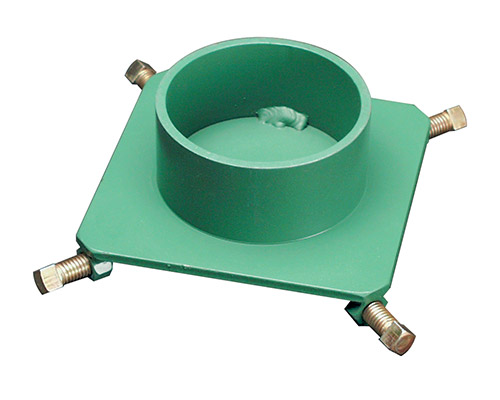

Self-Centering Stub End Holder

Self-centering stub end holder to hold stub end for butt fusion.

Spare Heater Plate Kit

Heater plates have an anti-stick coating and are required for butt fusion.

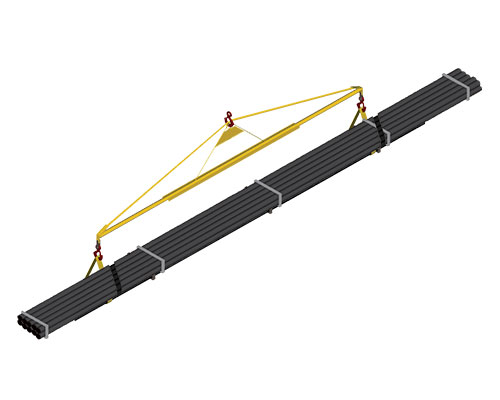

Spreader Bar

Ideal for handling 40′ bundles or a single joint of pipe. 6,000 lbs. maximum. 3,000 lbs. maximum

Stub End Holder

Holds stub end fittings for butt fusion to the end of a pipe.

SPECIFICATIONS

| MegaMc® 1236 Series 2 | |

| Machine | 6,885 lbs. (3,123 Kg) |

| 4-Jaw Carriage/strong> | 4,770 lbs. (2,164 Kg) |

| 3-Jaw Carriage | 1,745 lbs. (791 Kg) |

| Facer | 480 lbs (218 Kg) |

| Heater | 382 lbs (173 Kg) |

| Spreader Bar | 200 lbs (90.7 Kg) |

| Shipping Weight | 6,925 lbs (3,142 Kg) |

| MegaMc® 1236 Series 2 | |

| System Pressure | 2300 PSI (158 BAR) Max. |

| Hydraulic Reservoir Capacity | 28 Gallons (106 Liters) |

| Motor | 20HP, 3 Phase, 240V |

| MegaMc® 1236 Series 2 | |

| Heater Power | 20,461 Watt |

| Facer Power | Hydraulic |

| Input Voltage Requirements | 220V – 240V, 50/60Hz, 3Ph |

| Minimum Power Requirements | 39.4 kVA / 37.7 kW |

| Plug Type | I |

| MegaMc® 1236 Series 2 | |

| Frame | Welded steel construction |

| Front Axle | Articulating |

| Brake | Mechanical |

| MegaMc® 1236 Series 2 | |

| Tires | 6.90 – 9NHS, 75 PSI Max. |

| Transportation | Pulled via towing ring |

| Lifting | Lift points and lifting assembly |

| MegaMc® 824 | |||

| Machine | Shipping Container | ||

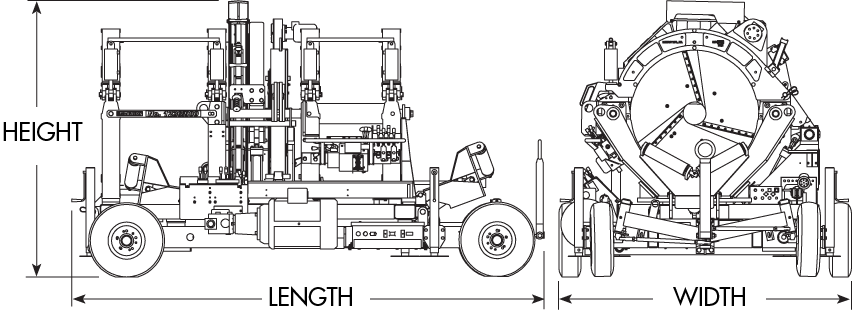

| Length | 131″ (3,327 mm) | 138″ (3,506 mm) | |

| Width | 83″ (2,108 mm) | 83″ (2,109 mm) | |

| Height | 78″ (1981 mm) | 85″ (2159 mm) | |

REVOLUTIONARY SIZE AND SKILLS

Versatility and power combined to build our MegaMc® fusion machines. Their main feature is that they are large diameter machines that give the flexibility characteristic of smaller diameter machines. Strong and resistant they are able to resist any climate and work in the most adverse conditions, in trench and in the smallest spaces.

NO LIFTING

REQUIRED

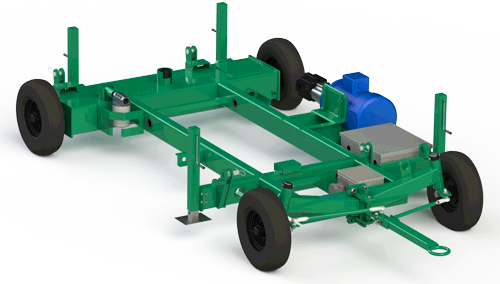

THE CHASSIS WITH WHEELS GIVES EASY WORK HANDLES

For longer pipes of medium and large diameters, this type of machine provides the necessary comfort in the workplace thanks to its portability. For each melting area the rolled machines are towed very simply, remaining stationary as they melt and the pipe rods are dragged.

HYDRAULIC

POWER

POWERFULL HYDRAULIC SYSTEM THAT WILL ASSIST ALONG ALL THE FUSION FUNCTIONS

All the functions where a lot of force is required are carried out without any problem thanks to its hydraulic system. Both the clamping and unblocking of the jaws and the fast and efficient face of the pipe ends are hydraulically operated. This function greatly helps to raise and lower the pipe of the machine. The reflector and the heater also work hydraulically, indexing from left to right and piloting in and out of the fusion machine. There is also a bar that protects the car in the area of the hydraulic car collector.

DATALOGGER®

COMPATIBLE*

THE EASIEST WAY TO RECORD & ANALYZE ALL YOUR FUSION JOINT DATA

All of the medium- and large-diameter Rolling machines are compatible with McElroy DataLogger. This is a small handheld computer that is responsible for documenting and analyzing the key parameters that are happening throughout the merger process. Later all this data is used to verify that all steps and fusion procedures are adequate before installation. The joint DataLogger records can be stored and analyzed in Vault, our server on the Internet. This allows a better classification, faster and easier, a labeling and an exchange of joint records by machine, articulation, operator, device or work.

MULTIPLE

CYCLINDER OPTIONS

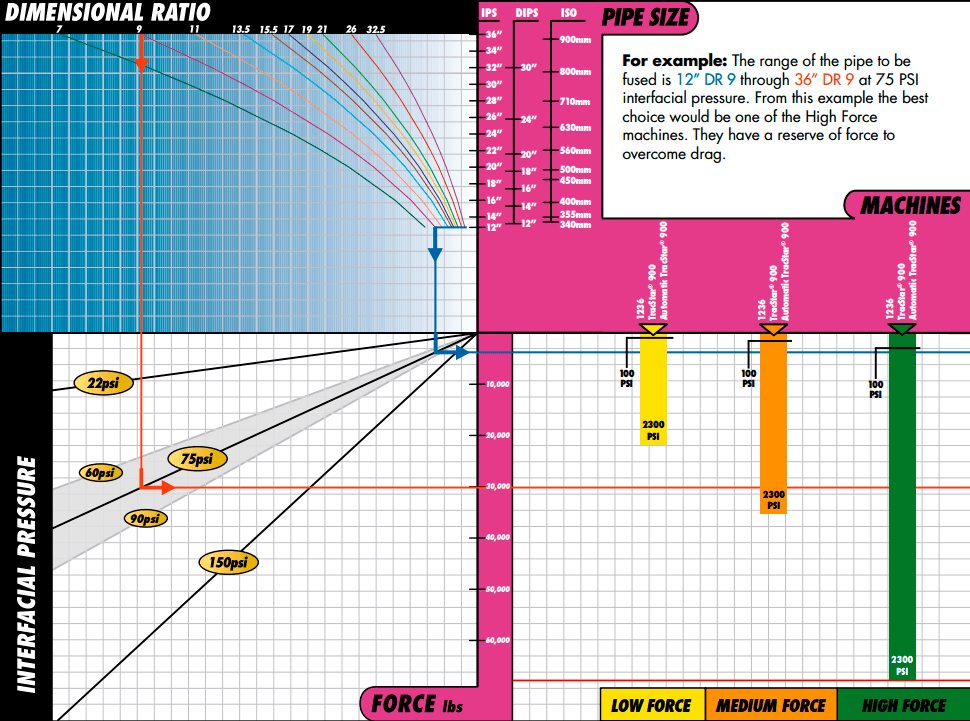

DESIGNED FOR ALL KINDS OF JOBSITE DEMANDS

Our MegaMc machines are available in a wide variety of different cylinder forces to suit every type of work and project. The type of pipe, the characteristics of each job, the fusion standards … These are variables that must be taken into account when choosing the MegaMc machine that best suits what you are looking for.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| Rolling 28 | Rolling 250 | Rolling 412 | Rolling 618 | MegaMc® 824 | MegaMc® 1236 | MegaMc® 1648 | MegaMc® 1600 | MegaMc® 2065 | |

| Patented Centerline Guidance System for equal distribution of force around the joint | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Industry standard semi-automatic hydraulic control system | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| DataLogger® compatible | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Powerful hydraulic facer for facing the toughest pipe with ease | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Advanced blade design for smooth face and long life | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| ISO-compliant industrial Teflon-coated heater plates | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Hard-anodized aluminum wear surfaces for corrosion resistance | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Removable 3- or 4-jaw carriage for close quarter use | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Available in Combination Unit (CU) for sidewall fusion | ✓ | ✓ | |||||||

| Large capacity 2-stage hydraulic pump for cool oil at max operating pressure | ✓ | ✓ | |||||||

| Lightweight heater design with 45-degree handle to prevent overheating | ✓ | ✓ | |||||||

| Microprocessor-controlled heater | ✓ | ✓ | ✓ | ✓ | |||||

| Thrust-bearing-equipped clamp knobs to minimize force required to clamp and round pipe | ✓ | ✓ | ✓ | ✓ | |||||

| High-force cylinder machine available | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Medium-force cylinder machine available | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Low-force cylinder machine available | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| On-board generator for powering heater | ✓ | ✓ | |||||||

| Gas-powered models available | ✓ | ✓ | |||||||

| Hydraulic pipe lifts | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Heater and facer can be easily converted to top-loading for confined spaces | ✓ | ✓ | |||||||

| Rugged outriggers for added stability | ✓ | ✓ | ✓ | ✓ | |||||

| 4-jaw carriage only | ✓ | ✓ | |||||||

| Hydraulic clamping available (standard on all MegaMc machines) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Hydraulic pivoting heater and facer | ✓ | ✓ | ✓ | ||||||

| Removable fourth jaw for enhanced convenience in fusing prefabricated fittings onto the pipe | ✓ | ||||||||

| Automatic hydraulic heater stripping to improve open and close times | ✓ |