THE BEST MACHINE TO INSTALL OUTPUT FUSIONS SIMPLE, ACCURATE AND QUICKLY

The Hornet is another of McElroy’s machines to be a pioneer because it has everything integrated into exit fusions for polystyrene tubes. A robust construction and innovative design that allows both machine and exit hole and connector fusion are perfectly aligned throughout the process. In this way, more efficient and secure mergers are achieved with fewer operators.

ALL ALIGNED THANKS TO YOUR EXCLUSIVE DESIGN

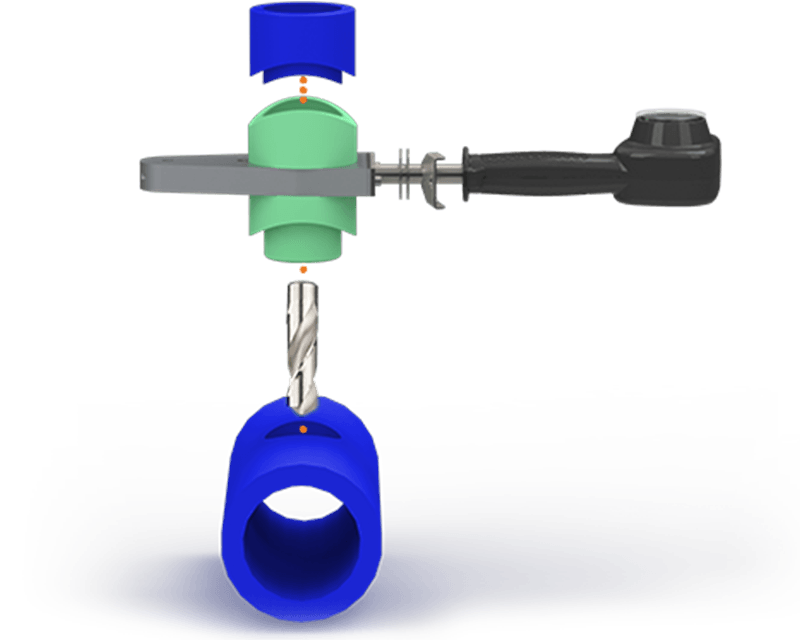

A design that was a pioneer in the industry. Integral machine, all in one. The machine itself is aligned alone in the center of the main tube. The car is then guided and allows the drilling of an exit hole, the heating of the tube and the fusion without the need to reposition the machine. This results in more precise mergers and fewer errors.

SAFE, EFFICIENT

AND REPETIBLE

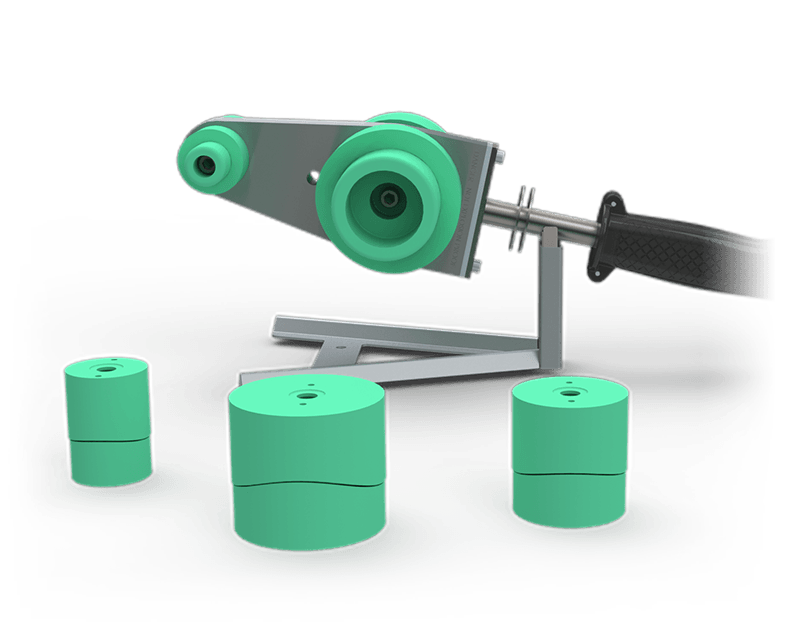

One of the most innovative machines for manual fusion in recent times. The Hornet has a V-shaped base design, with self-centering capability. A single operator will be able to automatically align the machine in the center of the main tube. Easily change the connector and bit adapters in and out of the car. This way you will get efficient operations. The rack mechanism facilitates the operations are safe and do not give problems. A band integrated in the ratchet holds the machine firmly in place and expands to fit a range of tube sizes up to 630 mm.

VERY LIGHT

AND COMPACT

It only weighs 11 pounds and is capable of output fusions from any angle. Ideal for aerial and vertical mergers in very small work spaces.

USE THE HEADS AND HEATERS FOR LACE THAT ALREADY MCELROY HAS

For all those polypropylene tubes from 20mm to 63mm in ducting up to 630mm, this machine works with all heads for McElroy saddle output fusions. A Teflon coating on all the adapters for lace makes the life of these longer. The Hornet uses McElroy’s small heaters that have their own dial thermometer and microprocessor to control the temperature as accurately as possible.

LEADERS OF THE

PLASTIC PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| Hornet | |

| Annodized aluminum wear surfaces for corrosion resistancet | ✓ |

| Quick-change drill and fitting adapter for efficient fusions | ✓ |

| Rack-and-pinion drive for smooth operation | ✓ |

| Self-centering base design ensures fusion operations align on center of pipe | ✓ |

| Integrated ratchet strap allows operation across wide range of pipe sizes | ✓ |

| Lightweight and compact | ✓ |

| Three-position carriage lock | ✓ |