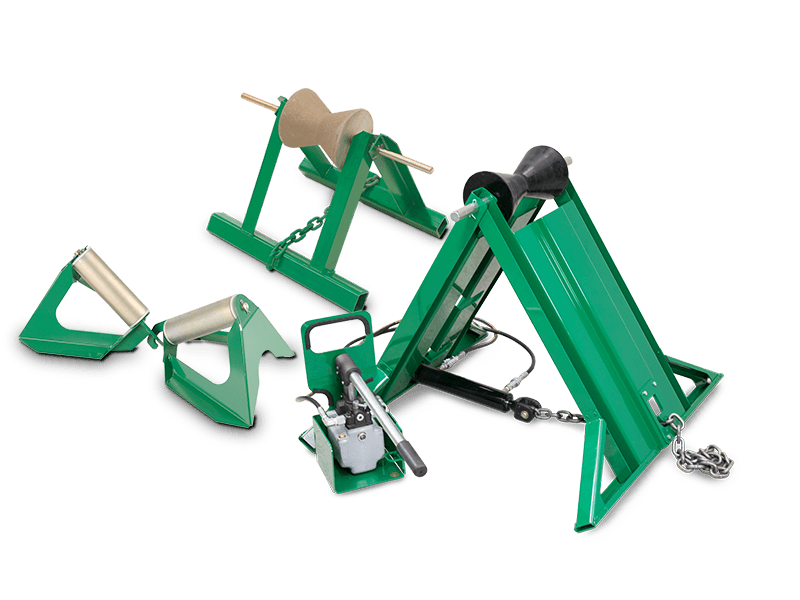

MEGAMC PIPE STANDS

Avoid the wear of your machines, facilitate the fusion process and reduce all the tension thanks to our pipe supports. Adjust the tubes in parallel to the machine to place them and adjust them to uneven ground.

Increase your productivity and instead of moving the fusion machines, pull the molten pipe through the machine. This way you will be able to roll up a new bar to make the mergers. With this you can organize the pipe in one location keeping your fusion machines in one place without moving them. This also minimizes the downtime between the fusion joints.

PARTS & ACCESSORIES FOR THE PIT BULL 250

Highlighted substitution parts and accessories

Hydraulic Pump Kit

For use on any Pipe Stand with manual-height adjustment.

Hydraulic Pipe Stand Valve/Hose Kit

Two section valve and one set of extension hoses to power a hydraulic stand from an 824/630 or 1236/900 machine.

Extension Hoses

One set of extension hoses to power second hydraulic pipe stand.

SPECIFICATIONS

| Part Number | 14 | 26 | 28 | 250 | 412 | 618 | 500 | 824 | 630 | 1236 | 900 | 1648 | 2065 | 1600 | |

| 14 Pipe Stand * | 422801 | ✓ | |||||||||||||

| 28 Pipe Stand ** | 4842401 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Pipe stand with manual chain height adjustment | AT5066701 | ✓ | ✓ | ✓ | |||||||||||

| Pipe stand with hydraulic height adjustment (No Pump Kit) | AT5066702 | ✓ | ✓ | ✓ | |||||||||||

| Pipe Stand with Hydraulic Height Adjustment (Includes Pump Kit) | AT5066703 | ✓ | ✓ | ✓ | |||||||||||

| Large Hydraulic Pipe Stand | T9055701 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Large Standard Pipe Stand | T9055801 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Heavy-Duty Pipe Stand | 4823901 | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| 2065 Pipe Stand | 6314001 | ✓ | ✓ | ||||||||||||

| 8″ – 36″ MegaMc Pipe Stand Gas powered | 3645001 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| 8″ – 36″ MegaMc Pipe Stand Diesel powered | 3645002 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| 12″ – 65″ MegaMc Pipe Stand Gas powered | 6513501 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| 12″ – 65″ MegaMc Pipe Stand Diesel powered | 6513502 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Part Number | Weight | |

| 14 Pipe Stand * | 422801 | 37 lbs (16.8 Kg) |

| 28 Pipe Stand ** | 906501 | 64 lbs (29 Kg) |

| Pipe stand with manual chain height adjustment | AT5066701 | N/A |

| Pipe stand with hydraulic height adjustment (No Pump Kit) | AT5066702 | N/A |

| Pipe Stand with Hydraulic Height Adjustment (Includes Pump Kit) | AT5066703 | N/A |

| Large Hydraulic Pipe Stand | T9055701 | 350 lbs (159 Kg) |

| PLarge Standard Pipe Stand | T9055801 | 240 lbs (109 Kg) |

| Heavy-Duty Pipe Stand | 4823901 | 595 lbs (270 Kg) |

| 2065 Pipe Stand | 6314001 | 1,025 lbs (465Kg) |

| 8″ – 36″ MegaMc Pipe Stand Gas powered | 3645001 | 2,160 lbs (980 Kg) |

| 8″ – 36″ MegaMc Pipe Stand Diesel powered | 3645002 | 2,160 lbs (980 Kg) |

| 12″ – 65″ MegaMc Pipe Stand Gas powered | 6513501 | 3,025 lbs (1,372 Kg) |

| 12″ – 65″ MegaMc Pipe Stand Diesel powered | 6513502 | 3,025 lbs (1,372 Kg) |

| Part Number | Weight | |

| 14 Pipe Stand * | 422801 | 2,500 lbs (1,134 Kg) |

| 28 Pipe Stand ** | 906501 | 2,500 lbs (1,134 Kg) |

| Pipe stand with manual chain height adjustment | AT5066701 | 2,750 lbs (1,247 Kg) |

| Pipe stand with hydraulic height adjustment (No Pump Kit) | AT5066702 | 2,750 lbs (1,247 Kg) |

| Pipe Stand with Hydraulic Height Adjustment (Includes Pump Kit) | AT5066703 | 2,750 lbs (1,247 Kg) |

| Large Hydraulic Pipe Stand | T9055701 | 4,500 lbs (2,041 Kg) |

| PLarge Standard Pipe Stand | T9055801 | 4,500 lbs (2,041 Kg) |

| Heavy-Duty Pipe Stand | 4823901 | 6,500 lbs (2,948 Kg) |

| 2065 Pipe Stand | 6314001 | 11,000 lbs (4,989 Kg) |

| 8″ – 36″ MegaMc Pipe Stand Gas powered | 3645001 | 9,000 lbs (4,082 Kg) |

| 8″ – 36″ MegaMc Pipe Stand Diesel powered | 3645002 | 9,000 lbs (4,082 Kg) |

| 12″ – 65″ MegaMc Pipe Stand Gas powered | 6513501 | 16,000 lbs (7,257 Kg) |

| 12″ – 65″ MegaMc Pipe Stand Diesel powered | 6513502 | 16,000 lbs (7,257 Kg) |

Pipe Rollers

WORK SMARTERLY

Our rollers will not only save you time, but will reduce the tension and damage the operator does to move the pipe. You will find our rollers for a wide range of pipes that can range from 1 «IPS to 65» outside diameter. These rollers are capable of handling heavy load pipes with a maximum capacity of 16,000 pounds. Combine the rollers you need to create the best workflow in your workplace. In this way you can achieve increased workflow, productivity and profitability.

MIX

AND MATCH

DEVELOP THE BEST CONFIGURATION FOR YOUR PLACE OF WORK

All our pipe supports can be used together to create a workplace that is as efficient as possible. In addition, all pipe rollers can be used with the vast majority of fusion machines and accessories such as QuickCamp or PolyHorse. In this way you will increase your productivity. Almost all of our rollers can be adjusted and adapted to uneven terrain, ensuring that the pipe is supported at the same height as the melting machine. Also facilitating alignment and refining. Pipe supports and low profile rollers allow long lengths of pipe to be taken through the machine instead of moving the joint equipment to the joint, minimizing downtime between mergers.

REDUCE THE CEPA AND USE LESS EQUIPMENT

Less work and more efficiency thanks to the McElroy pipe rollers. Our PolyPorter for example combine the mechanical advantage of a platform with the functionality of a tube holder. A single operator can lift, position and align all types of tubes up to 8 «DIPS. The vast majority of our pipe supports are adjusted hydraulically. This helps to align the pipes in the fusion machine more quickly. And will support pipes from 3 «to 65». This is a great advantage, as you do not need extra lifting equipment. All our rollers have a sealed ball bearing that will always guarantee that the tubes roll easily without any problem and without impediments.

PROTECT

YOUR PIPES

AVOID PIPELINES TOUCHING THE SOIL AND DAMAGING

You can place our rollers in sections along a long pipe that comes from the fusion machine itself along the entire pipe. So the pipes will slide more easily. The rollers are very useful if you want the pipe to be always clean and well away from the ground. With our low profile rollers and MegaMc rollers, you can make curve runs at considerable distances. All McElroy pipe rollers resist tips and minimize drag on pipes.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| PolyPorter® | Low Profile Rollers | MegaMc® Rollers | Pipe Stands | |

| Combines the advantages of a dolly and a pipe stand | ✓ | |||

| One person can easily load a length of pipe without straint | ✓ | |||

| Pipe easily slides through the roller into the fusion machine | ✓ | ✓ | ||

| Jack enables height of machine to be raised | ✓ | |||

| Modular design | ✓ | ✓ | ✓ | |

| Keeps pipe clean and off the ground | ✓ | ✓ | ✓ | ✓ |

| Allows for curved pulls | ✓ | ✓ | ||

| Compact storage | ✓ | ✓ | ||

| Tip resistant | ✓ | ✓ | ✓ | ✓ |

| Minimizes drag on the pipe | ✓ | ✓ | ✓ | ✓ |

| Sealed ball-bearing construction | ✓ | ✓ | ✓ | ✓ |

| Minimizes pipe damage | ✓ | ✓ | ✓ | ✓ |

| Stackable for transport 52 rollers on semi trailer | ✓ | |||

| Easily lifted with chain, straps or forks | ✓ | |||

| Hydraulically-adjustable option | ✓ | |||

| 1″ IPS – 4″ DIPS | ✓ | ✓ | ✓ | |

| 2″ IPS – 6″ DIPS | ✓ | ✓ | ✓ | |

| 2″ IPS – 8″ DIPS | ✓ | ✓ | ✓ | |

| 4″ IPS – 12″ DIPS | ✓ | ✓ | ✓ | |

| 6″ IPS – 18″ OD | ✓ | ✓ | ✓ | ✓ |

| 6″ IPS – 20″ OD | ✓ | ✓ | ✓ | ✓ |

| 8″ IPS – 24″ OD | ✓ | ✓ | ✓ | ✓ |

| 12″ IPS – 36″ OD | ✓ | ✓ | ✓ | |

| 16″ OD – 48″ OD | ✓ | ✓ | ✓ | |

| 20″ OD – 65″ OD | ✓ | ✓ |