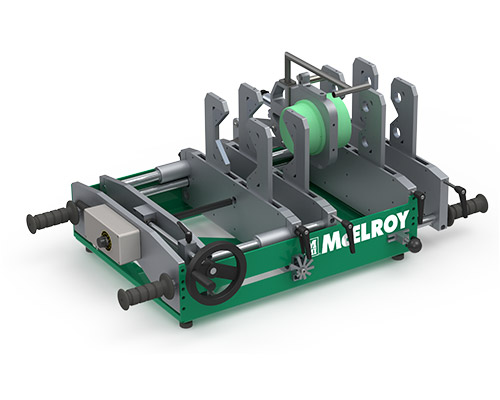

SMARTFAB™ 125

20mm – 125mm (½» – 4″)

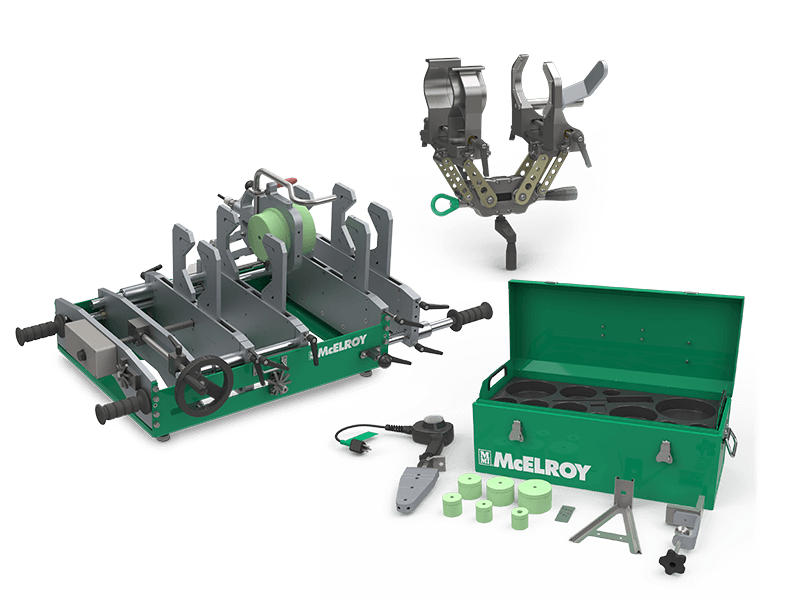

The SmartFab 125 is a tabletop machine that intelligently connects pipes and fuse connections for polypropylene pipe systems. It is a portable and versatile design that allows you to use the machine on any flat surface and merge throughout the day accurately.

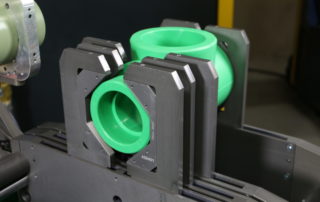

Among its advanced features include innovative inserts to reduce the ovality of pipes and accessories, a pivoting heater to conveniently place the accessories located on each side of the machine and individual clamping jaws that fit any pipe size and accessory market.

PARTS & ACCESSORIES FOR SPIDER 125

Highlighted substitution parts and accessories

«Type PP» Adapter Setup Kit

Setup blocks and depth star to be used with new style (PP) heater adapters. Replaces previous Q and D adapter types.

Depth Gauge Tool

Aids in marking appropriate depth for socket fusions.

Heater Adapter Sets

Used to heat pipe and fitting. All adapters have an anti-stick coating. 20-63m and 63-125mm.

Insulated Heater Sling

Protects heater and helps maintain a constant temperature.

Individual Heater Adapters

Used to heat pipe and fitting. All adapters have an anti-stick coating.

Pipe Support Stand

Height is adjustable to properly support, position and align pipe to be fused. 8″ Pipe Stand.

PolyPorter®

Aids in lifting pipe into the fusion machine and also performs as a pipe stand.

Large Heater Auxiliary Handle Kit

Handle assist for large adapters.

Rotary Pipe Cutters

Easily cut pipe up to 125mm. 10-90mm and 63-125mm.

Shipping Container

Shipping container for fusion machine, inserts and adapters.

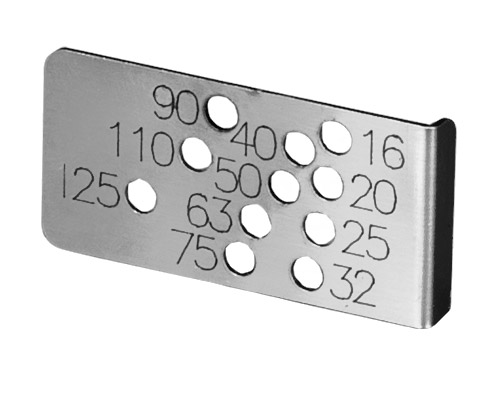

SmartFab Inserts

Surface-hardened for longer life. All inserts are serrated for maximum grip.

Socket Tooling Storage Box

Storage box for socket tooling and accessories. Includes universal storage tray to organize tooling.

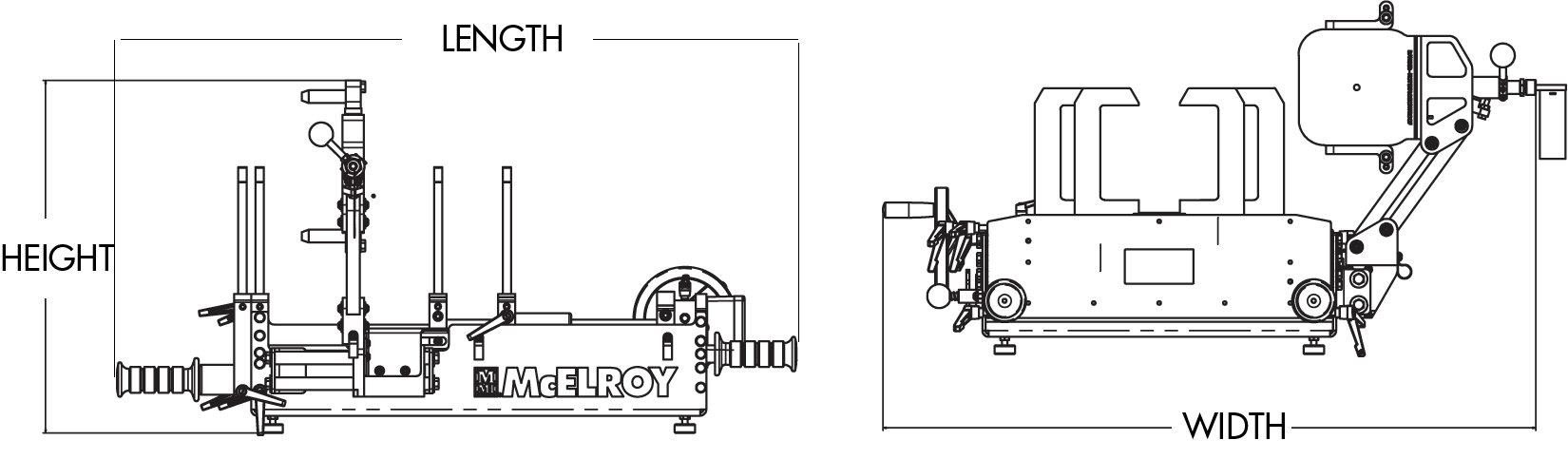

SPECIFICATIONS

| SmartFab™ 125 | |

| Machinee | 145 lbs (65.8 Kg) |

| SmartFab™ 125 | |||

| Heater Retracted | Heater Extended | ||

| Length | 40.1″ (1,019.2 mm) | 40.1″ (1,019.2 mm) | |

| Width | 30.8″ (782.3 mm) | 38″ (965.2 mm) | |

| Height | 16″ (406 mm) | 20.5″ (520.7 mm) | |

FUSION OF EASY USE AND PERFORMED BY A SINGLE OPERATOR

There is nothing faster and more accurate for the installation of polypropylene pipe systems like our socket fusion tools. They are very simple tools to use and only require an operator to perform the mergers. Thanks to this you will save time and money, the workplace will be more productive. By needing a single operator, you will have more workers to perform other jobs that need to be performed simultaneously.

MULTIPLE MACHINE

OPTIONS

AT THE WORKPLACE OR AT THE STORE

All tools for socket fusion are available to weld pipes from 16mm to 125mm (⅜ «- 4»). With just one tool you can make fusions of various pipe diameters, giving our tools greater flexibility at the same time to carry out different mergers during a working day We have socket fusion tools for each type of work, for example we have tools to merge pipes and accessories with hand tools, mergers in confined spaces, ceilings, floors, walls, mergers of joint pipes and accessories in the store on a desktop machine.

ACCESSORIES AND TOOLS

FOR ALL MARKET TUBE BRANDS

Our socket fusion tools are always the first choice of any operator since with them it is possible to merge with all brands of polypropylene tubes and accessories that are currently on the market, including PP-R (Polypropylene Random Copolymer) and the newest generation PP-RCT (Polypropylene Random Copolymer Crystalline Temperature). The advantages of using this type of material in pipes unlike other thermoplastic materials used in previous years, is that they do not corrode or leak over time.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| Socket Kits | Spider 125 | SmartFab 125 | |

| Hand-operated | ✓ | ✓ | ✓ |

| Toolless adjustment | ✓ | ✓ | ✓ |

| Fits all pipe brands of polypropylene pipe | ✓ | ✓ | ✓ |

| Teflon-coated socket adapters and heaters | ✓ | ✓ | ✓ |

| Thermostatically-controlled heater to provide constant fusion pressure | ✓ | ||

| Serviceable heaters, including the electronics | ✓ | ||

| Compact, lightweight | ✓ | ✓ | |

| No inserts necessary | ✓ | ||

| D-ring for easy lifting | ✓ | ||

| HDPE fusion capability | ✓ | ||

| Jaws or inserts that maintain roundness of pipe | ✓ | ✓ | |

| Strong gearbox and self-locking drive handle | ✓ | ✓ | |

| Custom toolbox/work bag | ✓ | ✓ | |

| Heater pivots 180° so the machine, pipe and fitting never has to be repositioned | ✓ | ||

| Jaws clamp individually and are size independent, allowing a greater combination of pipe and fittings | ✓ | ||

| Uses standard McElroy heater adapters | ✓ | ||

| ideal for prefabrication of large assemblie | ✓ |