GUIDED SIDE BEND TESTER

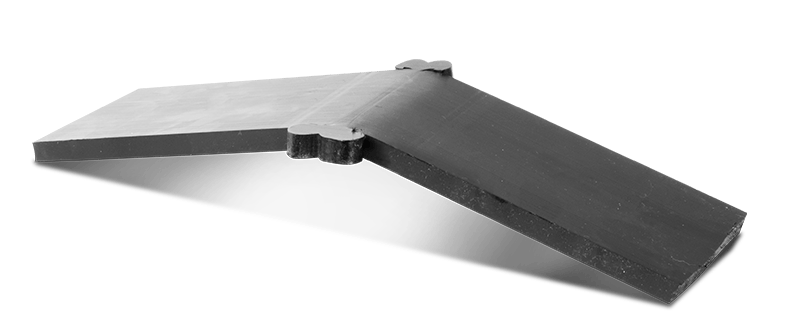

Quickly and qualitatively test fusion joints in the field with our traction tester. Make quick comparisons between the integrity of the joint and the main pipeline with the double reduced section coupons. A manual pump system tests 2 «IPS coupons and larger tubes (wall up to 5» thick).

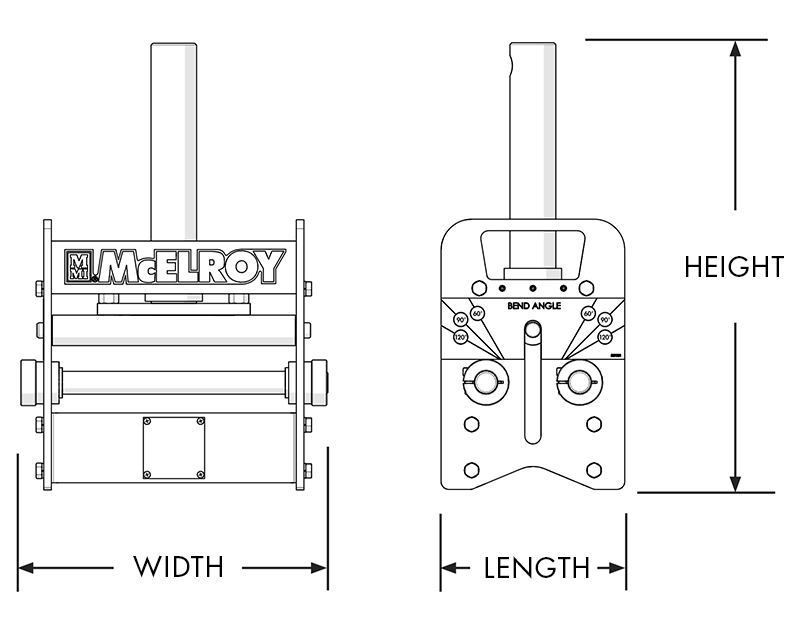

SPECIFICATIONS

| Guided Side Bend Tester | |

| Machine | 31 lbs (14.1 Kg) |

| Guided Side Bend Tester | |

| Maximum Test Coupon Thickness | ½» |

| Mandrel Diameter | 1″ |

| Guided Side Bend Tester | |

| Machine | |

| Length | 6″ (152.4 mm) |

| Width | 10.04″ (255 mm) |

| Height | 14.59″ (370.6 mm) |

TESTING TOOLS

A PIECE OF MIND IN YOUR PIPELINE

Never leave pipes put at random. A well-installed plastic pipe offers great durability and longevity and can be operational for decades. Therefore, we always recommend using our assurance tools to ensure all your merger operations and to know that your mergers comply with all standards.

PROOF OF FUSION JOINTS IN THE FIELD

In the past, to carry out a joint test, a piece of coupon had to be cut from the pipeline and sent to a laboratory to analyze it and wait for the results to return. Nowadays, thanks to the McElroy In Field traction tester and the guided lateral curved tester, any operator is able to do this test quickly, easily and with all the quality guarantees in the same place of work.

RAPID RESULTS THANKS TO A MANUAL HYDRAULIC FEED

The Side Guided Bending Tester and Tester and the In Field Traction Tester have hydraulic hand pumps that help perform persistent tests in the workplace without the need for additional power. The guided bending tester makes a quick and safe «double return» test, placing the entire thickness of the wall under tension to validate the ductility of the joint. In the case of the Field Tensile Tester, the test is destructive with 2 «IPS coupons and larger with a wall up to 5» thick. Do all the tests in just a few minutes to make sure the joints are 100% reliable.

QUALIFY OPERATORS, STRENGTH AND FUSIBILITY OF PIPES AND ACCESSORIES

Use our tools when you are about to start a new project or at the beginning of a new working day to assess the machine operator, the melting process and the pipe materials. With the field voltage tester and the guided lateral curvature tester you can perform a quick analysis in the same place of work, while the McNsapper will give you a deeper test that meets the ASTMF2634 standard for laboratory test procedures that they use tensile tests.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty

ADITIONAL FEATURES

| Guided Side Bend Tester | In Field® Tensile Tester | McSnapper® | |

| Tensile with impact testing machine | ✓ | ||

| Meets requirements of ASTM F2634 laboratory testing procedures | ✓ | ||

| Provides accurate testing for fused joints | ✓ | ✓ | ✓ |

| Testing up to 2.6” wall thickness | ✓ | ||

| Qualitative testing of the ductility of a joint | ✓ | ✓ | |

| Faster, easier and safer than traditional bend tests | ✓ | ||

| Can test coupons from 1″ to 7-inch-thick pipe walls | ✓ | ||

| Field suitable | ✓ | ✓ | |

| Lightweight | ✓ | ✓ | |

| Hydraulic hand-pump system powers coupon test | ✓ | ✓ | |

| Can produce coupons from up to 5-inch thick pipe wall | ✓ | ||

| Template accommodates 2” IPS and larger pipe | ✓ | ||

| Process takes minutes, not days or weeks | ✓ | ✓ |