LARGE DIAMETER PIPE COMES TO A NEW REVOLUTION WITH TALON 2000

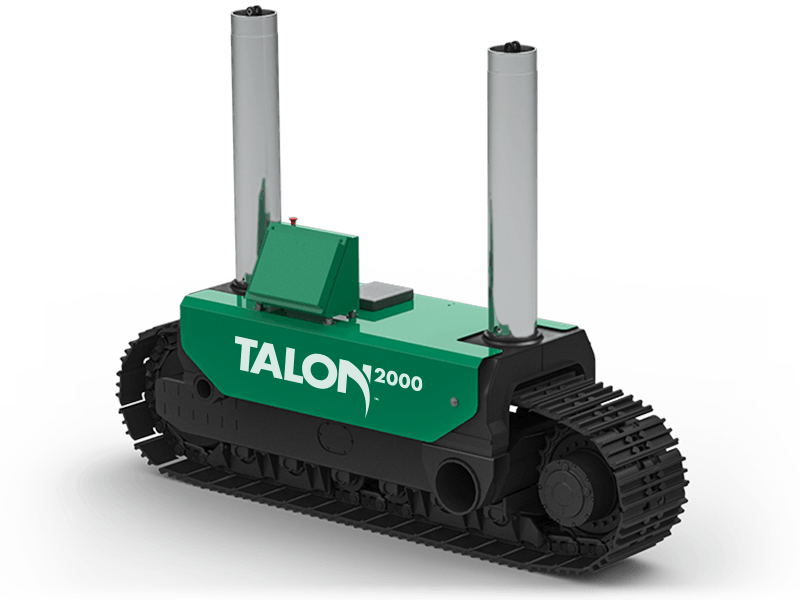

The Talon 2000 is the largest McElroy machine that has been manufactured so far. This machine for fusing large diameter pipes has been specially designed to replace all those obsolete infrastructures and increase capacity for a variety of applications that are currently in demand. The Talon 2000 has its own self-propelled vehicle that safely lift large diameter pipes from the ground, place them to merge them and pass them from the joint to the joint along the pipeline. In order to place the heater and the facer in the fusion machine safely and precisely, the machine has a fast action facer and an electric indexer.

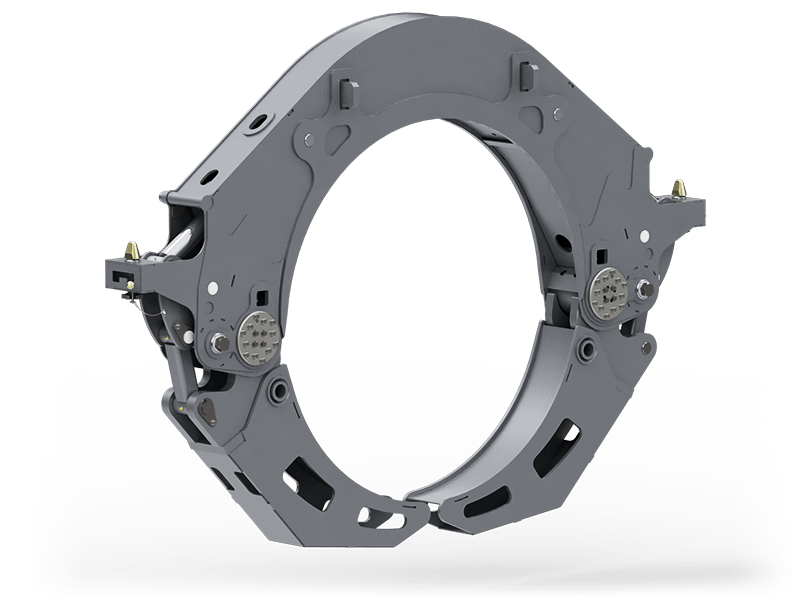

A COMPLETELY RENEWED

DESIGN FOR THE JAWS

LOADS TUBES BY ITSELF FROM THE GROUND

A new way of working where large diameter pipes are used. The Talon 2000 has been specifically designed so that its jaws pick up the pipes of the ground and align them in the machine itself. This great function avoids the use of additional heavy equipment and significantly increases the efficiency of the work. In addition to offering much safer working conditions, being the machine who performs all the heavy lifting.

SELF-CONTAINED

AND SELF-PROPELLED

BUILT FOR PIPELINING

Its generator on board and diesel engine make this machine is completely autonomous and can be driven from the union to the union of the pipe. No additional machine is necessary, it works by means of a set of steel tracks that are self-propelled. All loading and merging operations are very safe and efficient thanks to a wireless remote control. The Talon 2000 also has a ground tracking and tilt control to better align the pipes and irregular terrain.

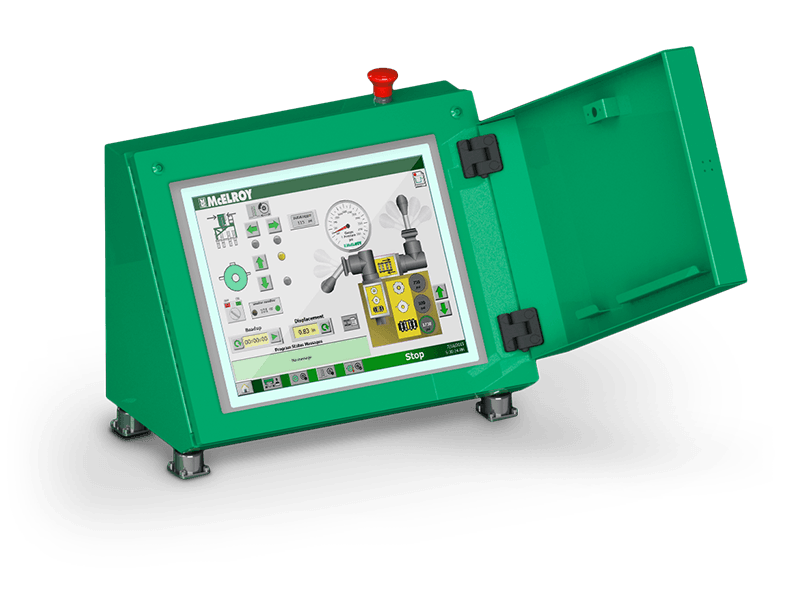

TOUCH

SCREEN

INTERFACE AND TACTILE CONTROLS BUT SAME INTERFACE AS ALWAYS

All fusion operations of the Talon are controlled through the touch interface. This station has been specially designed to mimic the controls of other of our McElroy machines. In this way all the fusion work will be easier and more familiar. For maintenance operations, McElroy technicians will access the Talon interface remotely to provide a real-time solution in the workplace.

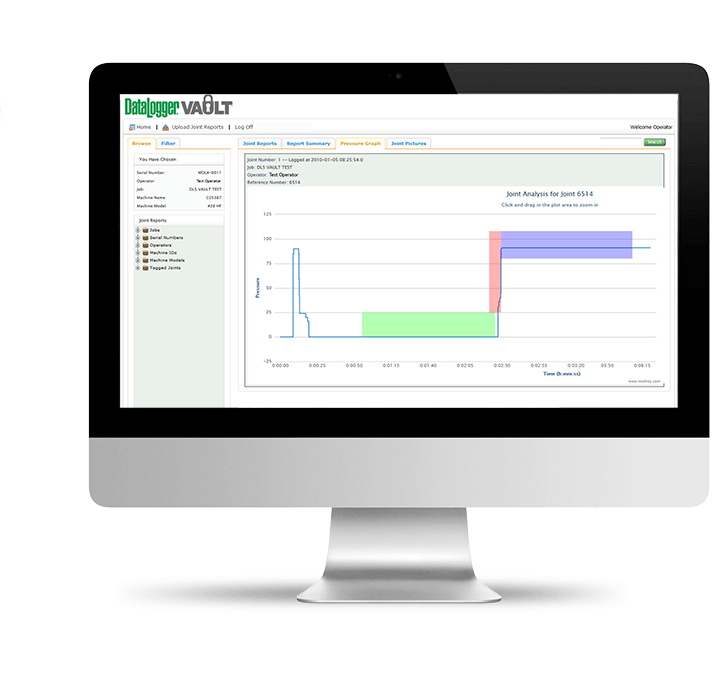

REGISTER ALL THE DATA

OF THE MERGER BOARD

DATALOGGER® VAULT ™ COMPATIBLE

In order to guarantee that all the fusion procedures have been carried out correctly before installation, the machine has an integrated function that records all this data. Then you can access all that information collected through the DataLogger® Vault ™. This new software has a secure and own server so you can sort, label, share and store in a much simpler and faster way all the records of the mergers, articulation, operator that had at that moment, that you are doing with the Talon.

LEADERS OF THE PLASTIC

PIPE WELDING INDUSTRY

MAXIMUM PERFORMANCE ALWAYS GUARANTEED

All Plastic Pipe Welding machines and equipment are specifically designed to withstand the most adverse conditions and climates. We guarantee that our machines will last for years. But if that were not enough for you, all our machines come with the maximum warranty period possible in the field of plastic welding, 5 years warranty.

ADITIONAL FEATURES

| Talon 2000 | |

| Self-loads pipe from the ground | ✓ |

| Self-contained, self-propelled | ✓ |

| Track-mounted for maneuverability | ✓ |

| Terrain following and pitch control to better align with pipe | ✓ |

| Top-loading heater and facer, no cranes necessary | ✓ |

| Electric-powered indexer accurately positions heater and facer | ✓ |

| Patented Centerline Guidance System for equal distribution of force around the joint | ✓ |

| Carriage converts to 1 fixed jaw with 3 movable jaws for easy tie-in and fitting fusions | ✓ |

| Efficient facer design removes up to 1″ of pipe per side in under 8 minutes | ✓ |

| Wireless remote control ensures safe, efficient working environment and precise machine placement | ✓ |

| Built-in datalogging feature records fusion joint data and syncs with the DataLogger® Vault™ for storage and analysis | ✓ |

| Remote-access, real-time troubleshooting* | ✓ |

* Requires a data-enabled SIM card