If you wish to double your daily welding, we will explain how.

With this machine we can weld the double welding of 250mm pipe lines daily.

Over the years as HDPE has been installed in pipelines worldwide there have been numerous welding standards created, almost one for each country, for example UNE, UNI, DVS, WIS, ANSI, ASTM.

The ISO standards were created in an effort to harmonize the various standards and create one set that would encompass the best procedures and maximize the quality of HDPE welding. After an analysis of all the available standards, ISO agreed on the three summarized below.

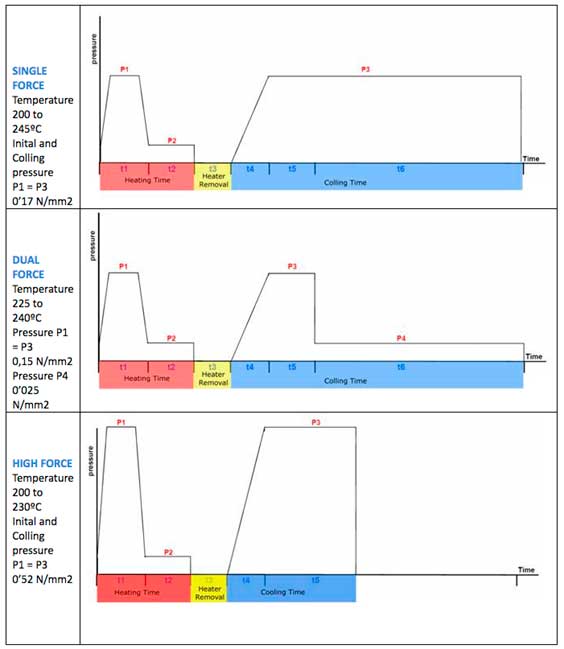

ISO SINGLE FORCE; This is the most used in Europe (DVS)and uses a pressure of 0.17N/mm2 in the heating and cooling process and a longer period for the cooling.

ISO DUAL FORCE; This regulation (WIS) is equal than the Single Force (DVS),but in this case using two pressures for the cooling, one part applying 0.15 N/mm2 of pressure and the rest applying 0.025 N/mm2 pressure.

ISO HIGH FORCE; This regulation is the most used in EEUU, and its main characteristic is that provides 0.52 N/mm2 of pressure along all the heating and cooling process, that represents three times more pressure ,and the cooling time is half than the Single Force (DVS) and Dual Force (WIS)

Hereunder, we are showing to you, a pressures and times chart for each regulation.

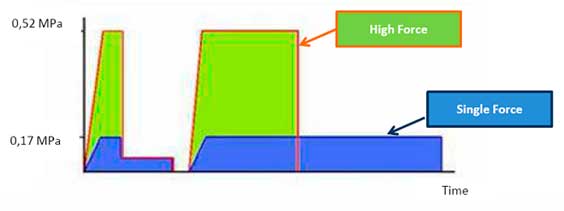

Quality of Joint: The quality of the joint is the same under any of the three ISO methods. All methods have been used for many years with great results, the method one chooses is simply a matter of preference. McElroy machines can fuse any of the standards but with the productivity of the McElroy machines in combination with the productivity gains of the ISO high force method, jobs can be done twice as fast.

As we can see in the cart, the ISO High Force needs half of the cooling time than the ISO Single Force (DVS) and Dual Force (WIS), this is a significant factor for reduce the installation cost, due that with the ISO High Force, can be welded double pipeline in one day than with the Single Force (DVS) and Dual Force (WIS).

This High productivity using the ISO High Force cause, that at the end of the work, could be able to perform in half of the time, that we will need using the Single force (DVS) and Dual Force (WIS).

For this project performed in India were used machines with ISO HIGH FORCE welding, were installed 3.500mts. of 900mm. pipelines in 62 days solely, meanwhile using the Single Force (DVS) and Dual Force (WIS) machines would be spend just around 184 days.( obtaining a saving time of 122 days). In this project was saved more time reason of besides of use the regulation ISO HIGH FORCE, the type of used machines made the set up shorten too.